Lathe, metal (Challenger 1660G) ID:46: Difference between revisions

(→Power Feed: add vid) |

Michael.fiss (talk | contribs) (→Practical Project: added practical project files) |

||

| (8 intermediate revisions by one other user not shown) | |||

| Line 56: | Line 56: | ||

==Jank== | ==Jank== | ||

===Carriage Lock=== | |||

If the carriage doesn't freely/easily move in the X direction, there's a fat hex bolt head sticking up on the right side of it that needs loosening. | |||

(add pic here) | |||

===Power Feed=== | ===Power Feed=== | ||

Note that while <u>generally gears/speeds shouldn't be changed while the lathe is in motion</u>, from https://forum.protospace.ca/t/can-t-get-lathe-power-feed-to-work/3568/8<blockquote>Set it to a lowish speed like 400 or less and bump the jog button. Then start wiggling leavers while it’s coasting down and watch the drive shaft and screw. You’ll feel it when it engages and the shafts will start spinning… | |||

The threading lead screw and the power feed drive shaft are taken off at different points in the gear train. It is possible to jiggle a leaver and get one to start spinning while the other is still not engaged properly and requires further jiggling. | The threading lead screw and the power feed drive shaft are taken off at different points in the gear train. It is possible to jiggle a leaver and get one to start spinning while the other is still not engaged properly and requires further jiggling. | ||

The XYWZ lever is the worst and usually requires persuasion to engage. The gears are all straight cut, and all may require sufficient wigglage before they cooperate. And the number dial is keep turning until it works. It’s about 1/4 past the number you want.</blockquote> | The XYWZ lever is the worst and usually requires persuasion to engage. The gears are all straight cut, and all may require sufficient wigglage before they cooperate. And the number dial is keep turning until it works. It’s about 1/4 past the number you want.</blockquote>[[File:20180206_230213_720p.mp4|frameless]] | ||

<br /> | |||

==Documents== | ==Documents== | ||

=== Reference === | |||

*[http://www.southern-tool.com/store/birmingham_lux-1640-g_lathes.php Sales page for 1640T and 1660T models] | *[http://www.southern-tool.com/store/birmingham_lux-1640-g_lathes.php Sales page for 1640T and 1660T models] | ||

| Line 72: | Line 80: | ||

*[https://wiki.protospace.ca/images/5/5e/LUX-Matter_1600_Series_Instruction_Manual.pdf 1500/1600 Instruction Manual and Parts List] | *[https://wiki.protospace.ca/images/5/5e/LUX-Matter_1600_Series_Instruction_Manual.pdf 1500/1600 Instruction Manual and Parts List] | ||

=== Training === | |||

(training material linked here?) | |||

=== Practical Project === | |||

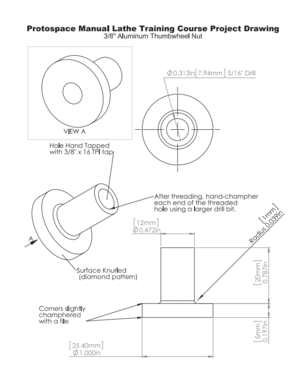

[[:File:Protospace Lathe Training Project (Jan 2016).pdf|Protospace Lathe Training Project Instructions (pdf)]] | |||

[[File:Lathe Practical Project.png|none|thumb|Lathe Practical - Aluminum Thumbscrew]] | |||

<br /> | <br /> | ||

==Tooling== | ==Tooling== | ||

Latest revision as of 19:46, 8 April 2025

| |

| Type | Metal lathe |

| Make/Model | Challenger 1660G (aka Birmingham LUX 1660G or YCL-1660) |

| Serial number | ?? |

| Original owner | Protospace |

| Loan status | Owned by Protospace |

| Arrival date | 2015-12-22 |

| Location | Metal shop |

| Functional status | Working |

| Usage permissions | Open to full members |

| Certification | Metal Cutting & Manual Lathe |

| Wiki-ID | 46 |

| Label | 1.0" 1.5" 2.0" |

Specifications

All from the 1640T/1660T page listed in the Documents section unless noted.

- Dimensions: 29" deep × 72" long × ?? tall (according to John W)

- Mass: ~4000–5000 lbs

- Motor: 7.5 hp, 3-phase, 220 V

- 36–1800 RPM spindle speed in 12 steps

- Capacities

- Swing over bed: 16"

- Swing over cross slide: 10"

- Distance between centers: 60"

- Swing in gap: 60"

- Width of bed: 24"

- Headstock

- Spindle nose: ASA D1-6

- Spindle bore: 2 1/16" or 2 1/8"

- Spindle taper: MT 6

- Spindle speeds: 36, 60, 82, 93, 158, 215, 302, 510, 695, 786, 1328, 1800 rpm

- Threads & feeds

- Imperial threading: 2–72 TPI (45 kinds)

- Metric threading: 0.2–14mm (40 kinds)

- Module pitch threading: 0.3–3.5 M.P. (18 kinds) (for making shafts for worm gears)

- DP threading: 8–44 DP (21 kinds)

- Longitudinal feed range: 0.002"–0.04" ipr

- Cross feed range: 0.001"–0.02" ipr

- Carriage

- Cross slide travel: 8 1/4"

- Compound slide travel: 5 1/4"

- Tailstock

- Center taper: MT 4

- Quill travel: 6 1/4"

- Quill diameter: 2 1/16"

- Coolant pump

- Safety foot brake

Jank

Carriage Lock

If the carriage doesn't freely/easily move in the X direction, there's a fat hex bolt head sticking up on the right side of it that needs loosening.

(add pic here)

Power Feed

Note that while generally gears/speeds shouldn't be changed while the lathe is in motion, from https://forum.protospace.ca/t/can-t-get-lathe-power-feed-to-work/3568/8

Set it to a lowish speed like 400 or less and bump the jog button. Then start wiggling leavers while it’s coasting down and watch the drive shaft and screw. You’ll feel it when it engages and the shafts will start spinning…

The threading lead screw and the power feed drive shaft are taken off at different points in the gear train. It is possible to jiggle a leaver and get one to start spinning while the other is still not engaged properly and requires further jiggling.

The XYWZ lever is the worst and usually requires persuasion to engage. The gears are all straight cut, and all may require sufficient wigglage before they cooperate. And the number dial is keep turning until it works. It’s about 1/4 past the number you want.

Documents

Reference

- Sales page for 1640T and 1660T models

- According to those in the know (Danny P and John W) there are three manuals for this machine:

- 1640G/1660G Instruction Manual and Parts List

- 1640T/1660T Instruction Manual and Parts List

- 1500/1600 Instruction Manual and Parts List

Training

(training material linked here?)

Practical Project

Protospace Lathe Training Project Instructions (pdf)

Tooling

History

This lathe was bought by Protospace using funding approved for the purchase of new machine tools at the December 2015 members' meeting. It was picked up and brought to Protospace on 2015-12-22 along with the ACRA mill and the new 80-gallon air compressor. It replaces Kyle Paavola's lathe; it has equivalent capability. It came with the following accessories:

- 3-jaw chuck

- 4-jaw chuck

- Big steady rest

- Taper attachment

- 40-position tool post and one tool holder with a carbide tool holder in it

- Live center

- A carriage stop with a micrometer

- Coolant pump