Laser cutter (Trotec Speedy 300) ID:107: Difference between revisions

Jump to navigation

Jump to search

(radical reformatting; added lens/mirror warning; added account agreement) |

|||

| Line 13: | Line 13: | ||

}} | }} | ||

==Specs== | ==Quick Specs== | ||

Supported file formats: | * '''Working bed size:''' 730mm x 430mm (28 3/4" x 17" ish) | ||

DXF, CDR, SVG, AI | * '''Engraving resolution:''' 1000DPI | ||

* '''Kerf:''' 0.1mm | |||

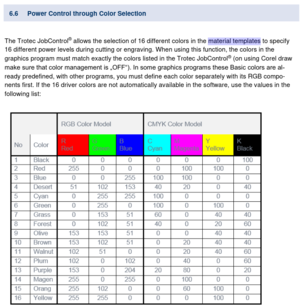

* '''Supported file formats:''' Anything that can be "printed" to [https://www.troteclaser.com/en-ca/laser-machines/jobcontrol JobControl] with the appropriate vectors, fills and line formatting. Trotec's [https://www.youtube.com/c/TrotecLaserCanada/videos excellent tutorials] and our [https://docs.google.com/presentation/d/1_RdW1xh5ltwHSCs7e7BQaaY60jo0sO8frpAQ2GgcG5w/edit?usp=sharing training courses] are done in [https://www.coreldraw.com/en/ CorelDRAW], so the computer attached to our laser provides a licensed copy. Other popular software includes [https://inkscape.org/ Inkscape], [https://www.autodesk.ca/en/products/autocad/overview Autodesk AutoCAD] and [https://www.adobe.com/ca/products/illustrator.html Adobe Illustrator], generating files such as DXF, CDR, SVG, AI, PDF, etc. | |||

* '''Maximum material thickness:''' generally 1/2", with thicker materials possible using multiple passes, resulting in poor edge finish due to kerf. | |||

== Usage and Billing Policies == | |||

* [https://drive.google.com/file/d/0By-vvp6fxFekUF9WZG9jaFdwMHc/view?resourcekey=0-GxIydSgSjerHfn-1onI0gw Trotec Laser Account Agreement] | |||

==Documentation== | ==Documentation== | ||

{{Warning|It is imperative to complete a [[chlorine test]] on materials before working with them in any laser cutter.}}{{Warning|Per training and usage agreements, the lens and mirror must be checked and cleaned: | |||

* before use | |||

* during continuous use, or | |||

* when used with unfamiliar material, and | |||

* after use.}} | |||

[https://wiki.protospace.ca/images/e/ef/Speedy-300-Manual-EN.pdf Speedy 300 Product Manual] | [https://wiki.protospace.ca/images/e/ef/Speedy-300-Manual-EN.pdf Speedy 300 Product Manual] | ||

| Line 39: | Line 49: | ||

Maximum material thickness: 1/2" | Maximum material thickness: 1/2" | ||

Higher thicknesses generally have worse edge finishing because of beam spreading out at top and bottom | Higher thicknesses generally have worse edge finishing because of beam spreading out at top and bottom | ||

Please try any new, strange, or unknown materials in the Rabbit first, and closely watch them for flame or dense black smoke. | Please try any new, strange, or unknown materials in the Rabbit first, and closely watch them for flame or dense black smoke. | ||

Revision as of 20:23, 23 April 2022

| |

| Type | Trotec |

| Make/Model | Speedy 300 |

| Serial number | S3-4699 |

| Original owner | Protospace |

| Loan status | Owned by Protospace |

| Arrival date | December 2016 |

| Location | Bay 108, near the door to the front rooms |

| Functional status | Working |

| Usage permissions | Members & Friends Only |

| Certification | Must complete Laser Certification and Trotec Certification |

| Wiki-ID | 107 |

| Label | 1.0" 1.5" 2.0" |

Quick Specs

- Working bed size: 730mm x 430mm (28 3/4" x 17" ish)

- Engraving resolution: 1000DPI

- Kerf: 0.1mm

- Supported file formats: Anything that can be "printed" to JobControl with the appropriate vectors, fills and line formatting. Trotec's excellent tutorials and our training courses are done in CorelDRAW, so the computer attached to our laser provides a licensed copy. Other popular software includes Inkscape, Autodesk AutoCAD and Adobe Illustrator, generating files such as DXF, CDR, SVG, AI, PDF, etc.

- Maximum material thickness: generally 1/2", with thicker materials possible using multiple passes, resulting in poor edge finish due to kerf.

Usage and Billing Policies

Documentation

| It is imperative to complete a chlorine test on materials before working with them in any laser cutter. |

Per training and usage agreements, the lens and mirror must be checked and cleaned:

|

JobControl 11.2 Operation Manual

Engraves can be done with embedded image files (PNG et al) or with vector fills (Unlike rabbit which does not receive fill information)

Maximum material thickness: 1/2" Higher thicknesses generally have worse edge finishing because of beam spreading out at top and bottom

Please try any new, strange, or unknown materials in the Rabbit first, and closely watch them for flame or dense black smoke. The lens is very exposed on the Trotec and thick smokey materials, like resin-y woods, rubber, or some plastics, can very quickly damage the machine and potentially the lungs of everyone in the space. Start with low power tests and work your way up.