Air compressor, 80-gallon (Ingersoll Rand T30): Difference between revisions

(Created page with "{{Template:EquipmentPage |toolname= Two-stage reciprocating compressor |model=Ingersoll-Rand T30 242ON5 |serial=30T 758634 |owner=Kyle Paavola |loanstatus= Long Term Loan |arr...") |

m (added arrival date) |

||

| (12 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Equipment page removed | ||

|toolname= Two-stage reciprocating compressor | | removedby = Kyle Paavola | ||

|model=Ingersoll-Rand T30 242ON5 | | removalreason = ended membership | ||

|serial=30T 758634 | | removaldate = 2015-12-02 | ||

|owner=Kyle Paavola | | replacements = [[air compressor, 60-gallon (Campbell Hausfeld)]] and [[air compressor, 80-gallon (MAXair Premium)]] | ||

|loanstatus= Long Term Loan | | toolname = Two-stage reciprocating compressor | ||

|arrived= | | model = Ingersoll-Rand T30 242ON5 | ||

|location= Right of the welding bench | | serial = 30T 758634 | ||

|status= Working | | owner = Kyle Paavola | ||

|permission= Members and friends only | | loanstatus = Long Term Loan | ||

|certification= To be determined. Do not start if you don't feel qualified | | arrived = Before 2014-10-04 | ||

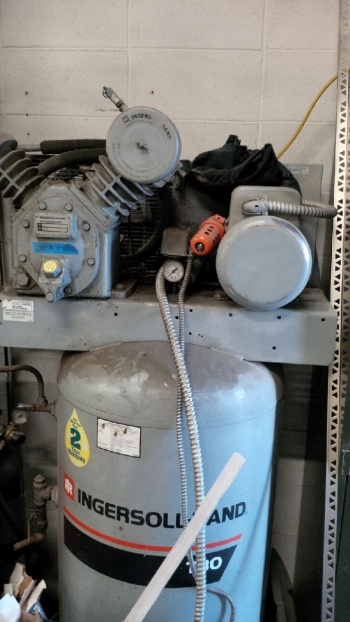

|itemphoto=[[File:Reciprocating_compressor.jpg|350px|thumb|right|]] | | location = Right of the welding bench | ||

| status = Working | |||

| permission = Members and friends only | |||

| certification = To be determined. Do not start if you don't feel qualified | |||

| itemphoto = [[File:Reciprocating_compressor.jpg|350px|thumb|right|]] | |||

}} | }} | ||

[[Category:Compressed air tools (removed)]] | |||

==Specs== | ==Specs== | ||

This compressor is an industrial grade machine to be treated with some degree of respect. This 5HP compressor is electrically driven by 208V single phase available through the same pigtail that powers the TIG welder. | This compressor is an industrial grade machine to be treated with some degree of respect. This 5HP compressor is electrically driven by 208V single phase available through the same pigtail that powers the TIG welder. | ||

[[File:208V_pigtail.jpg|x350px]] | |||

This compressor is capable of substantially higher pressure than most air tools can tolerate, which is why its discharge pressure is regulated to 100 psi. Do not adjust this regulator without consulting with Kyle. Doing so may damage your equipment or hurt you seriously. | |||

[[File:Regulator_and_filter.jpg|x350px]] | |||

==Use and Maintenance== | ==Use and Maintenance== | ||

verbatim from the sticker right on the compressor but just in case you have not read it: | |||

CAUTION: TURN OFF POWER BEFORE SERVICING | |||

Daily: | |||

*Drain any condensate from ceceiver and traps | |||

*Check for any unusual noise or vibration | |||

Weekly | |||

*Check for proper oil level | |||

[[File:Compressor_cranck_case.jpg|x350px]] | |||

Monthly | |||

*Clean air filter | |||

*Clean all external parts of compressor and driver | |||

*Test relief valve manually for proper operation | |||

*Inspect entire air system for leaks | |||

*Inspect oil for contamination and change if necessary | |||

*Check belt tension and wear | |||

Every 3 months: | |||

*Change oil using an approved lubricant | |||

*Inspect valve assemblies | |||

for more information, check the operator's manual at: | |||

http://manualarchive.ingersollrandproducts.com/ir_pdfs/Compressed%20Air/Air%20Compressors/Reciprocating%20Compressor/22607402.PDF | |||

==Approved Lubricant== | ==Approved Lubricant== | ||

ONLY Ingersoll-Rand All season oil is currently approved for use in this compressor. You must check for the presence of oil in the compressor pan before operating this machine. | ONLY Ingersoll-Rand All season oil is currently approved for use in this compressor. You must check for the presence of oil in the compressor pan before operating this machine. | ||

==QR Code== | |||

[[File:Compressor_Wiki.png|x250px]] | |||

Latest revision as of 05:16, 24 April 2019

| This article is about a tool that is no longer at Protospace. Further information can be found below. |

- Type: Two-stage reciprocating compressor

- Make/Model: Ingersoll-Rand T30 242ON5

- Serial Number: 30T 758634

- Original Owner: Kyle Paavola

- Removed by: Kyle Paavola

- Removal Reason: ended membership

- Loan Status: Long Term Loan

- Arrival Date: Before 2014-10-04

- Removal Date: 2015-12-02

- Replacements: air compressor, 60-gallon (Campbell Hausfeld) and air compressor, 80-gallon (MAXair Premium)

- Location: Right of the welding bench

- Functional Status: Working

- Usage Permissions: Members and friends only

- Certification: To be determined. Do not start if you don't feel qualified

- Wiki-ID: [[{{{id}}}]]

Specs

This compressor is an industrial grade machine to be treated with some degree of respect. This 5HP compressor is electrically driven by 208V single phase available through the same pigtail that powers the TIG welder.

This compressor is capable of substantially higher pressure than most air tools can tolerate, which is why its discharge pressure is regulated to 100 psi. Do not adjust this regulator without consulting with Kyle. Doing so may damage your equipment or hurt you seriously.

Use and Maintenance

verbatim from the sticker right on the compressor but just in case you have not read it:

CAUTION: TURN OFF POWER BEFORE SERVICING

Daily:

- Drain any condensate from ceceiver and traps

- Check for any unusual noise or vibration

Weekly

- Check for proper oil level

Monthly

- Clean air filter

- Clean all external parts of compressor and driver

- Test relief valve manually for proper operation

- Inspect entire air system for leaks

- Inspect oil for contamination and change if necessary

- Check belt tension and wear

Every 3 months:

- Change oil using an approved lubricant

- Inspect valve assemblies

for more information, check the operator's manual at: http://manualarchive.ingersollrandproducts.com/ir_pdfs/Compressed%20Air/Air%20Compressors/Reciprocating%20Compressor/22607402.PDF

Approved Lubricant

ONLY Ingersoll-Rand All season oil is currently approved for use in this compressor. You must check for the presence of oil in the compressor pan before operating this machine.