Embroidery machine, CNC (Tajima TEJT II-C NEO 1501) ID:144: Difference between revisions

(→Troubleshooting: data button not working) |

Ian.hawkins (talk | contribs) m (→Documentation: Added new version of User's Guide) |

||

| Line 17: | Line 17: | ||

*[https://wiki.protospace.ca/images/7/7c/Tejtiic.pdf <nowiki>User Manual [pdf]</nowiki>] | *[https://wiki.protospace.ca/images/7/7c/Tejtiic.pdf <nowiki>User Manual [pdf]</nowiki>] | ||

*[https://wiki.protospace.ca/images/1/16/Tejtiic-2014-user-manual.pdf <nowiki>User Manual (2014)[pdf]</nowiki>] | |||

*[https://wiki.protospace.ca/images/7/74/Tajima-tejt-iic-neo-series-catalog.pdf <nowiki>Product Catalog [pdf]</nowiki>] | *[https://wiki.protospace.ca/images/7/74/Tajima-tejt-iic-neo-series-catalog.pdf <nowiki>Product Catalog [pdf]</nowiki>] | ||

*[https://web.archive.org/web/20151117050317/http://www.tajima.com:80/productinfo/2014090911263001.html Manufacturer's Product Page] | *[https://web.archive.org/web/20151117050317/http://www.tajima.com:80/productinfo/2014090911263001.html Manufacturer's Product Page] | ||

===Specs=== | ===Specs=== | ||

| Line 25: | Line 27: | ||

**75/11 size DBxK5 round shank needles | **75/11 size DBxK5 round shank needles | ||

*Thread: 40-weight top, 80-weight bobbin | *Thread: 40-weight top, 80-weight bobbin | ||

*Work Envelope Dimensions: | *Work Envelope Dimensions: | ||

**19.5” L x 14” D large hoop | **19.5” L x 14” D large hoop | ||

*up to 1,200 stitches per minute | *up to 1,200 stitches per minute | ||

*Cost: $8500.00 | *Cost: $8500.00 | ||

*Power Supply: 120V, max 220 Watts | * Power Supply: 120V, max 220 Watts | ||

*Overall Dimensions: | *Overall Dimensions: | ||

**32" Door Clearance | **32" Door Clearance | ||

**26.25" Width x 31.75" Depth x 31.5" Tall without stand (W 665mm * L 805mm * H 796 mm) | **26.25" Width x 31.75" Depth x 31.5" Tall without stand (W 665mm * L 805mm * H 796 mm) | ||

**170 lb. with stand | **170 lb. with stand | ||

===Materials=== | === Materials=== | ||

Bring your own backing. | Bring your own backing. | ||

| Line 54: | Line 56: | ||

#Insert stick into USB port at rear left side of machine | #Insert stick into USB port at rear left side of machine | ||

#Scan card on lockout device to power on Tajima | #Scan card on lockout device to power on Tajima | ||

#Choose your frame type at "Frame:" | #Choose your frame type at "Frame:" | ||

#*flat: the various flat circular green frames | #*flat: the various flat circular green frames | ||

#*cap: the round metal hat torture device | #*cap: the round metal hat torture device | ||

#"Initialize: On" allows the machine to home at calibrate, why would you ever turn this off? | #"Initialize: On" allows the machine to home at calibrate, why would you ever turn this off? | ||

#Load your file from USB stick by pressing the "Data" button and scrolling through the list | #Load your file from USB stick by pressing the "Data" button and scrolling through the list | ||

#"Color change:" | #"Color change:" | ||

#*'''auto''': if you'd like the machine to just run your color order | #*'''auto''': if you'd like the machine to just run your color order | ||

#*'''manual''': if you need to change fabrics or positions between colors/operations - '''STOP HERE, INSTRUCTIONS for "manual color change" are INCOMPLETE/UNTESTED! GET DEMO/HELP WITH THIS! DO NOT PASS THIS STEP, DO NOT PRESS GO, DO NOT COLLECT CRASHED MACHINE AND BROKEN NEEDLE -''' do update these instructions once you get it reliably figured out though... | #*'''manual''': if you need to change fabrics or positions between colors/operations - '''STOP HERE, INSTRUCTIONS for "manual color change" are INCOMPLETE/UNTESTED! GET DEMO/HELP WITH THIS! DO NOT PASS THIS STEP, DO NOT PRESS GO, DO NOT COLLECT CRASHED MACHINE AND BROKEN NEEDLE -''' do update these instructions once you get it reliably figured out though... | ||

#Type in your color change order - note this is in hexadecimal so 1-9 then 10 is typed using the "+10" button then 0 and shows up as A, so 11 is "+10" then 1 and will show up as B, etc. | #Type in your color change order - note this is in hexadecimal so 1-9 then 10 is typed using the "+10" button then 0 and shows up as A, so 11 is "+10" then 1 and will show up as B, etc. | ||

#Set the frame position by running a "Trace", it uses the needle/color shown on the bottom right corner | #Set the frame position by running a "Trace", it uses the needle/color shown on the bottom right corner | ||

#Make super extra double sure that your "Trace" will not crash the machine into the frame, and that the design will end up where you want it on your workpiece | # Make super extra double sure that your "Trace" will not crash the machine into the frame, and that the design will end up where you want it on your workpiece | ||

#Adjust the speed slider to the slower 1/3rd | #Adjust the speed slider to the slower 1/3rd | ||

#Press "Start" | #Press "Start" | ||

===Rethreading A needle=== | === Rethreading A needle=== | ||

To prepare thread: put new thread under NO TENSION and cut at an angle. This makes the thread end a wedge and un-frayed which is far easier to thread through the eye of a needle | To prepare thread: put new thread under NO TENSION and cut at an angle. This makes the thread end a wedge and un-frayed which is far easier to thread through the eye of a needle | ||

| Line 75: | Line 77: | ||

===Needle Replacement Procedure=== | ===Needle Replacement Procedure=== | ||

#Loosen Flathead screw, remove worn or damaged needle | # Loosen Flathead screw, remove worn or damaged needle | ||

#When installing needle, vertical groove faces user, seat needle fully into holder. | #When installing needle, vertical groove faces user, seat needle fully into holder. | ||

#Ensure vertical groove still aligned before tightening | #Ensure vertical groove still aligned before tightening | ||

| Line 83: | Line 85: | ||

===Changing a Spool=== | ===Changing a Spool=== | ||

#Load on new spool | # Load on new spool | ||

#Cut old spool. | #Cut old spool. | ||

#Tie end of old thread to new thread. Clip any extra and stray material so it does not get caught when you pull it through | #Tie end of old thread to new thread. Clip any extra and stray material so it does not get caught when you pull it through | ||

| Line 90: | Line 92: | ||

<br /> | <br /> | ||

==Troubleshooting== | ==Troubleshooting == | ||

====Machine Detected a Thread Breakage==== | ==== Machine Detected a Thread Breakage==== | ||

[https://forum.protospace.ca/t/troubleshooting-the-embroidery-machine-tip/2418 See this forum post] | [https://forum.protospace.ca/t/troubleshooting-the-embroidery-machine-tip/2418 See this forum post] | ||

==== Data Button Not Working ==== | ====Data Button Not Working==== | ||

See instructions below for Memory Capacity Exceeded Error. | See instructions below for Memory Capacity Exceeded Error. | ||

====2BA - Memory Capacity Exceeded Error==== | ====2BA - Memory Capacity Exceeded Error ==== | ||

Clear previous jobs stored in the memory: | Clear previous jobs stored in the memory: | ||

*Each time a job is loaded from the USB stick the job is transferred to the internal memory of the Tajima. | *Each time a job is loaded from the USB stick the job is transferred to the internal memory of the Tajima. | ||

| Line 107: | Line 109: | ||

*The 2BA error may occur instantly or near the end of the file load process depending on when the limit is reached. | *The 2BA error may occur instantly or near the end of the file load process depending on when the limit is reached. | ||

*If the internal memory is very full, pressing the Data button to pick a USB file will give no response as if the Data button is broken. | *If the internal memory is very full, pressing the Data button to pick a USB file will give no response as if the Data button is broken. | ||

*When the Tajima is too full to show the 2BA error, data can be deleted just as if the 2BA error had appeared. | * When the Tajima is too full to show the 2BA error, data can be deleted just as if the 2BA error had appeared. | ||

* | * | ||

*Press down to select | *Press down to select | ||

*3. Delete Data to remove a single job or to | *3. Delete Data to remove a single job or to | ||

*5. Initial Memory - to remove all jobs from memory and initialize internal storage[[File:TajimaDataM1.png|none|thumb|Data Menu]][[File:TajimaDataM3.png|thumb|Data Menu 3|alt=|none]]<br /> | *5. Initial Memory - to remove all jobs from memory and initialize internal storage[[File:TajimaDataM1.png|none|thumb|Data Menu]][[File:TajimaDataM3.png|thumb|Data Menu 3|alt=|none]]<br /> | ||

*There is no way to save a list of internal jobs out. | *There is no way to save a list of internal jobs out. | ||

*Keep a copy of your Jobs on a USB stick. | *Keep a copy of your Jobs on a USB stick. | ||

Revision as of 16:49, 11 December 2025

| |

| Type | CNC embroidery machine |

| Make/Model | Tajima TEJT II-C NEO 1501 |

| Serial number | 3127 |

| Original owner | Protospace |

| Loan status | N/A |

| Arrival date | Feb 9th, 2021 |

| Location | Sewing Room |

| Functional status | Waiting for training material |

| Usage permissions | ?? |

| Certification | Course |

| Wiki-ID | 144 |

| Label | 1.0" 1.5" 2.0" |

Documentation

Specs

- Single-head 15-needle

- 75/11 size DBxK5 round shank needles

- Thread: 40-weight top, 80-weight bobbin

- Work Envelope Dimensions:

- 19.5” L x 14” D large hoop

- up to 1,200 stitches per minute

- Cost: $8500.00

- Power Supply: 120V, max 220 Watts

- Overall Dimensions:

- 32" Door Clearance

- 26.25" Width x 31.75" Depth x 31.5" Tall without stand (W 665mm * L 805mm * H 796 mm)

- 170 lb. with stand

Materials

Bring your own backing.

Stick with 40wt polyester thread, others break a lot.

Supplies available at: Where to source tools and materials#Textiles

Bobbin

L-type bobbin, takes 80wt thread, threads clockwise out under spring and through metal eyelet, leave 2" tail. Observe lubing requirements before reinserting.

Quick Start

| This "cheat sheet" is not a substitute for proper training and confidence in operating this very nice and expensive machine! If you're feeling unsure, ask for help! |

- Digitize your file - software magic process steps go here - and copy onto special USB 1.0 stick

- Set up your material/workpiece and backing on the appropriate hoop or fixture, drum tight and evenly tensioned

- Insert stick into USB port at rear left side of machine

- Scan card on lockout device to power on Tajima

- Choose your frame type at "Frame:"

- flat: the various flat circular green frames

- cap: the round metal hat torture device

- "Initialize: On" allows the machine to home at calibrate, why would you ever turn this off?

- Load your file from USB stick by pressing the "Data" button and scrolling through the list

- "Color change:"

- auto: if you'd like the machine to just run your color order

- manual: if you need to change fabrics or positions between colors/operations - STOP HERE, INSTRUCTIONS for "manual color change" are INCOMPLETE/UNTESTED! GET DEMO/HELP WITH THIS! DO NOT PASS THIS STEP, DO NOT PRESS GO, DO NOT COLLECT CRASHED MACHINE AND BROKEN NEEDLE - do update these instructions once you get it reliably figured out though...

- Type in your color change order - note this is in hexadecimal so 1-9 then 10 is typed using the "+10" button then 0 and shows up as A, so 11 is "+10" then 1 and will show up as B, etc.

- Set the frame position by running a "Trace", it uses the needle/color shown on the bottom right corner

- Make super extra double sure that your "Trace" will not crash the machine into the frame, and that the design will end up where you want it on your workpiece

- Adjust the speed slider to the slower 1/3rd

- Press "Start"

Rethreading A needle

To prepare thread: put new thread under NO TENSION and cut at an angle. This makes the thread end a wedge and un-frayed which is far easier to thread through the eye of a needle

Thread needle front to back (away from user), raise thread end up and into spring to hold it there.

Needle Replacement Procedure

- Loosen Flathead screw, remove worn or damaged needle

- When installing needle, vertical groove faces user, seat needle fully into holder.

- Ensure vertical groove still aligned before tightening

- Tighten flathead screw

- Rethread the needle

Changing a Spool

- Load on new spool

- Cut old spool.

- Tie end of old thread to new thread. Clip any extra and stray material so it does not get caught when you pull it through

- Pull the old thread from the needle side. The new thread will get pulled through the tubing and tensioners automagically

- Cut new thread and rethread the needle

Troubleshooting

Machine Detected a Thread Breakage

Data Button Not Working

See instructions below for Memory Capacity Exceeded Error.

2BA - Memory Capacity Exceeded Error

Clear previous jobs stored in the memory:

- Each time a job is loaded from the USB stick the job is transferred to the internal memory of the Tajima.

- In Memory Mode - Multi, the job is added to the list of jobs.

- In Memory Mode - Single, the new job overwrites the last job held in internal memory.

- When the internal Tajima memory is full a 2BA error will occur after pressing Data and choosing the job file from the USB.

- The 2BA error may occur instantly or near the end of the file load process depending on when the limit is reached.

- If the internal memory is very full, pressing the Data button to pick a USB file will give no response as if the Data button is broken.

- When the Tajima is too full to show the 2BA error, data can be deleted just as if the 2BA error had appeared.

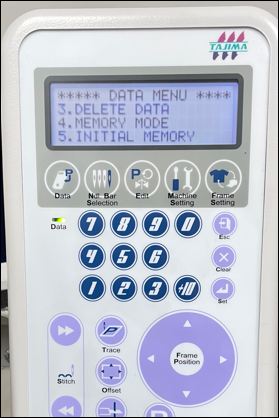

- Press down to select

- 3. Delete Data to remove a single job or to

- 5. Initial Memory - to remove all jobs from memory and initialize internal storage

- There is no way to save a list of internal jobs out.

- Keep a copy of your Jobs on a USB stick.

- It is convenient if you are doing multiple jobs in a single session to keep them in internal memory.

- Just remember jobs saved to the Internal Tajima memory may be cleared by the next member using the machine.

- As a curtesy to the next user who may be a beginner and not know about 2BA error, clear the memory at the end of your session

Stop Position Error (211)

A stop position error on the Tajima means that the Tajima stopped unexpectedly potentially due to a collision with the frame. To resolve the error perform the following steps:

- Dismiss the error using the red "O"/Stop key on the keypad.

- (Refer to the manual excerpt on the left for the following steps)

- Rotate the main shaft until the circled indicator disappears in the status display

- Perform a manual color change, by selecting a different color using the manual color change keys on the bottom right of the keypad. Once a different color is selected press Set to confirm the manual color change.

- Once the manual color change is complete you may resume your stiching.

If this happens when you first turn the machine on, the TEJT2-C series screen shows after you dismiss the error instead of the EMB START screen. The color change buttons have no effect. Change INITIAL:ON to INITIAL:OFF, then press Set. Follow the steps above to clear the error.