CNC router, mini (TD 3040) ID:141: Difference between revisions

No edit summary |

|||

| (37 intermediate revisions by 3 users not shown) | |||

| Line 10: | Line 10: | ||

| permission = Should take CAD and Tormac CNC courses | | permission = Should take CAD and Tormac CNC courses | ||

| certification = | | certification = | ||

| photo = | | photo = 141.jpg | ||

| id = 141 | | id = 141 | ||

}} | }} | ||

== Notes == | ==Notes== | ||

The effective bed size is | The effective bed size is 11" by 14". There are purple marker lines on the bed, that's the limit where the spindle can actually reach. | ||

The router is running on Mach3 (a program running on Windows | The router is running on Mach3 (a program running on Windows XP), so remember to select XP as operating system. | ||

The ER11 collet we currently have only accepts 1/8' bit shank. Maximum spindle speed is 13,500 RPM. The speed is controlled via a dial knob. As Mach3 can read and adjust spindle speed, | Note: If you wanted to use LinuxCNC (a Linux distro) instead, you would need to boot up the PC to Linux. Note that this document does not cover LinuxCNC at this time. It is not configured and you are on your own on that one. | ||

Also: we are working on an Arduino interface running GRBL, which will allow you to run other front end programs. As of this writing (Aug 28, 2021), this is a work-in-progress. | |||

The ER11 collet we currently have only accepts 1/8' bit shank. Maximum spindle speed is 13,500 RPM. The speed is controlled via a dial knob. As Mach3 can read and adjust spindle speed, but this feature is not currently implemented. | |||

All Axes are calibrated bang on (don't quote me on this, but the dial gauge says so); however, the backlash compensation must be disabled to achieve a smooth helical ramp in operation. More on this later, but for now if your project requires only straight line milling in and out (like milling a square pocket inside your stock) then feel free to re-enable backlash comp. | All Axes are calibrated bang on (don't quote me on this, but the dial gauge says so); however, the backlash compensation must be disabled to achieve a smooth helical ramp in operation. More on this later, but for now if your project requires only straight line milling in and out (like milling a square pocket inside your stock) then feel free to re-enable backlash comp. | ||

| Line 24: | Line 28: | ||

All old limit switches got replaced, soft limit settings in Mach3 are in place. Please keep soft limits on. | All old limit switches got replaced, soft limit settings in Mach3 are in place. Please keep soft limits on. | ||

==Test result== | |||

After calibration, we tested the machine with 2D Milling operation (Nested square pocket) and 3D Milling operation (Dome shape) and it churned out shapes nicely. (Image 2&3) | |||

== | I suggest that you keep the speed & feed rate conservative (i.e make it slow) and see how this machine plays with various materials, both wood and soft metal. I have no idea whether or not we can mill Aluminium chunk with this little bugger without wearing it out *prematurely* but I'm not an expert on this so your opinions are more than welcomed. | ||

==Usage== | |||

The machine runs on Mach3, the same software previously used on Tormac. Anyone who knows how to use the Tormac, or know what you are doing, or can hit E-Stop fast enough, or well, is curious enough and want to play with it, are welcome to use the machine. | |||

The basic procedure: | |||

- Use a 3D Modelling software to model your object (like Fusion360 or Solidworks) then have this software spit out the GCode needed to manufacture your object. | |||

- Launch Mach3 program, turn on CNC machine, do Homing sequence and Stock origin sequence | |||

- Feed this GCode into Mach3 and it will control the CNC machine to churn out the parts. | |||

- Possibly edit your G-Code to tweak a few things to get it right | |||

There is an introductory Fusion360 class for those who want to use this or the Tormac Metal CNC machine. | |||

There will also be a specific MiniCNC class offered once we have the bugs ironed out and the documentation created. | |||

==Instructions== | |||

[[File:Teacher.jpg]] | |||

*Step by Step [[MiniCNCBasics|Mini CNC Basic Operations]] instruction. | |||

<!-- Initial Draft "How to" document ==> [http://wiki.protospace.ca/images/1/15/141-Mini-CNC-Basics.pdf 141-Mini-CNC-Basics.pdf] --> | |||

== Enclosure == | ==Enclosure== | ||

While noise is not much | While noise is not much of an issue, this machine can generate lots of fine sawdust so you need to stand at the machine, pointing the shop-vac hose right at the spindle to minimize the dust. I think a machine of this size and weight, an enclosed box for it is manageable. | ||

== Training & Liability == | ==Training & Liability== | ||

Future (proper) training needed for this machine. | Future (proper) training needed for this machine. | ||

Use the machine as your own risk. Wear PPEs at all time. | Use the machine as your own risk. Wear PPEs at all time. | ||

== Samples == | ==History== | ||

[[File:141-a.jpg|200px | |||

*Refurbished and made operational by Andy Kornelson | |||

==Upgrade Requests== | |||

*Add a Height Sensor for non-metallic surfaces. I have a simple design that I will be working on. | |||

*maybe build a touch sensor (eg: http://fadedbits.com/2011/02/touchprobe/) or https://www.instructables.com/id/CNC-Manual-Touch-Probe/ | |||

*Add a Surface Mapping program (G-Code Ripper looks like a good one but needs a probe ) | |||

*Install a registration strip on the bed to allow for repeatable placement of holders and templates. ('''DONE''') | |||

*design and install improved hold-down clamps. ('''DONE''') | |||

==Upgrade History== | |||

*02/29/2020: Bought 2" x 5/16 stove bolts to replace M4 on hold down clamps. | |||

*03/03/2020: Replaced (added to inventory?) shorter bolts to hold down clamp. Ground heads down to allow them to pass the Allen head screws holding bed down. | |||

*03/07/2020: Updated GRUB config to remember last boot OS | |||

*03/10/2020: fabricated and installed registration strip out of acrylic. Aligned with bed to be parallel with x axis. See [[:file:141-registrationstrip.jpg|'''Picture of Registration Strip''']] | |||

*03/28/2021: Configured Desktop Shortcut to automatically run the profile "Mach3Mill (Metric)". Also added a "No Profile" shortcut if you want to select your own version. | |||

*03/28/2021: Configured Spinal On/Off. Use F5 to turn on/off, or click on the Manual Speed Control. | |||

. | |||

==Repairs Needed== | |||

*This is a placeholder for listing repairs that are needed | |||

==Repair History== | |||

*This is a placeholder for listing repairs that were performed | |||

==Samples== | |||

[[File:141-a.jpg|200px|alt text]] [[File:141-b.jpg|200px|alt text]] [[File:MiniCNC-Bed-Height.jpg|500px]]<br> | |||

Picture showing range of z motion. About 6cm max | |||

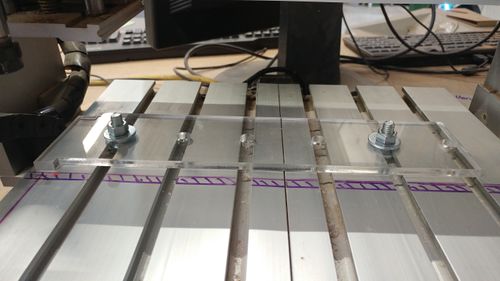

[[File:141-registrationstrip.jpg|500px]]<br> | |||

Registration Strip. Is easily removed if required but has been carefully aligned with the X axis. | |||

Latest revision as of 18:59, 20 January 2023

| |

| Type | TD 3040 Mini CNC |

| Make/Model | TD 3040 |

| Serial number | |

| Original owner | Configured by Andy |

| Loan status | |

| Arrival date | |

| Location | Laser / Storage area |

| Functional status | Working, ready for training |

| Usage permissions | Should take CAD and Tormac CNC courses |

| Certification | |

| Wiki-ID | 141 |

| Label | 1.0" 1.5" 2.0" |

Notes

The effective bed size is 11" by 14". There are purple marker lines on the bed, that's the limit where the spindle can actually reach.

The router is running on Mach3 (a program running on Windows XP), so remember to select XP as operating system.

Note: If you wanted to use LinuxCNC (a Linux distro) instead, you would need to boot up the PC to Linux. Note that this document does not cover LinuxCNC at this time. It is not configured and you are on your own on that one.

Also: we are working on an Arduino interface running GRBL, which will allow you to run other front end programs. As of this writing (Aug 28, 2021), this is a work-in-progress.

The ER11 collet we currently have only accepts 1/8' bit shank. Maximum spindle speed is 13,500 RPM. The speed is controlled via a dial knob. As Mach3 can read and adjust spindle speed, but this feature is not currently implemented.

All Axes are calibrated bang on (don't quote me on this, but the dial gauge says so); however, the backlash compensation must be disabled to achieve a smooth helical ramp in operation. More on this later, but for now if your project requires only straight line milling in and out (like milling a square pocket inside your stock) then feel free to re-enable backlash comp.

All old limit switches got replaced, soft limit settings in Mach3 are in place. Please keep soft limits on.

Test result

After calibration, we tested the machine with 2D Milling operation (Nested square pocket) and 3D Milling operation (Dome shape) and it churned out shapes nicely. (Image 2&3)

I suggest that you keep the speed & feed rate conservative (i.e make it slow) and see how this machine plays with various materials, both wood and soft metal. I have no idea whether or not we can mill Aluminium chunk with this little bugger without wearing it out *prematurely* but I'm not an expert on this so your opinions are more than welcomed.

Usage

The machine runs on Mach3, the same software previously used on Tormac. Anyone who knows how to use the Tormac, or know what you are doing, or can hit E-Stop fast enough, or well, is curious enough and want to play with it, are welcome to use the machine.

The basic procedure:

- Use a 3D Modelling software to model your object (like Fusion360 or Solidworks) then have this software spit out the GCode needed to manufacture your object. - Launch Mach3 program, turn on CNC machine, do Homing sequence and Stock origin sequence - Feed this GCode into Mach3 and it will control the CNC machine to churn out the parts. - Possibly edit your G-Code to tweak a few things to get it right

There is an introductory Fusion360 class for those who want to use this or the Tormac Metal CNC machine.

There will also be a specific MiniCNC class offered once we have the bugs ironed out and the documentation created.

Instructions

- Step by Step Mini CNC Basic Operations instruction.

Enclosure

While noise is not much of an issue, this machine can generate lots of fine sawdust so you need to stand at the machine, pointing the shop-vac hose right at the spindle to minimize the dust. I think a machine of this size and weight, an enclosed box for it is manageable.

Training & Liability

Future (proper) training needed for this machine.

Use the machine as your own risk. Wear PPEs at all time.

History

- Refurbished and made operational by Andy Kornelson

Upgrade Requests

- Add a Height Sensor for non-metallic surfaces. I have a simple design that I will be working on.

- maybe build a touch sensor (eg: http://fadedbits.com/2011/02/touchprobe/) or https://www.instructables.com/id/CNC-Manual-Touch-Probe/

- Add a Surface Mapping program (G-Code Ripper looks like a good one but needs a probe )

- Install a registration strip on the bed to allow for repeatable placement of holders and templates. (DONE)

- design and install improved hold-down clamps. (DONE)

Upgrade History

- 02/29/2020: Bought 2" x 5/16 stove bolts to replace M4 on hold down clamps.

- 03/03/2020: Replaced (added to inventory?) shorter bolts to hold down clamp. Ground heads down to allow them to pass the Allen head screws holding bed down.

- 03/07/2020: Updated GRUB config to remember last boot OS

- 03/10/2020: fabricated and installed registration strip out of acrylic. Aligned with bed to be parallel with x axis. See Picture of Registration Strip

- 03/28/2021: Configured Desktop Shortcut to automatically run the profile "Mach3Mill (Metric)". Also added a "No Profile" shortcut if you want to select your own version.

- 03/28/2021: Configured Spinal On/Off. Use F5 to turn on/off, or click on the Manual Speed Control.

.

Repairs Needed

- This is a placeholder for listing repairs that are needed

Repair History

- This is a placeholder for listing repairs that were performed

Samples

Picture showing range of z motion. About 6cm max

Registration Strip. Is easily removed if required but has been carefully aligned with the X axis.