CNC router, wood (Precix) ID:153

| |

| Type | Precix Wood CNC router |

| Make/Model | Industrial |

| Serial number | |

| Original owner | Protospace |

| Loan status | Current |

| Arrival date | Mar 26th, 2020 |

| Location | Wood Shop |

| Functional status | Works! |

| Usage permissions | Members |

| Certification | Must complete Basic CNC Wood Router course |

| Wiki-ID | 153 |

| Label | 1.0" 1.5" 2.0" |

Machine Overview

Bed size: 5'(1.524m) x 10'(3.048m) x 11"(0.2794m)

Axis Orientation: Y is the long one.

Max spindle RPM: 18000RPM (spindle is a AT/MT1073-140 from HSD mechatronics)

Spindle power: 2.2KW, 3HP Spindle type: VFD based motor. (VFD is a commander SK from control tech user manual, advance user manual)

Max feed rate: 750inch/min

Tool holder type: ER25 collets, we have 1/8", 1/4",3/8",1/2" (as of 05.11.2021)

Automatic tool changer: No

File units: Default units are imperial. you may switch to metric using gcode commands, it is recommended that you export imperial code.

File type accepted: .tap, .gcode, .txt

Machine control software suite: Mach3 skinned with physics anonymous Mach pack

Will do 3 axis moves?:Yes

Software

Mach3

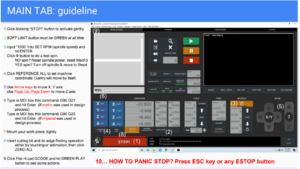

The Precix PC uses Mach3 to control the spindle and axes.

Mach3 has an optimized, custom screen set installed, although if you wish, you can change it back to the traditional screen. Just remember to return it to the custom set when you are finished.

Links to HOW TO Videos:

- MACH Support YouTube Channel

- "MACH3 Has Never Looked This Good." Video explaining our Mach3 Custom Interface that is installed on the Precix PC

VCarve

To create designs for routing, we have a makerspace-licensed version of VCarve Pro. This means you can download, install and run VCarve Pro Trial Edition on your home PC or Laptop and THEN LOGIN to access the Makerspace License. For free!

Follow this link to create a Vectric account linked to Protospace: https://portal.vectric.com/organization/shared-invite/X6Ds8uH2G5HfJKP6xjKr Then after installing the free trial and logging in you will have full use of the Makerspace version.

Once you've installed Vcarve, you can create files at home then export gcode from the licensed classroom and music workstations at Protospace.

Protospace instructions for installing VCarve Pro on WIndows and Mac: https://forum.protospace.ca/t/vcarve-pro-installation-instructions-mac-and-windows-precix-cnc/11838

General tutorials for installing and using VCarve Pro: https://portal.vectric.com/organization/238/makerspaceEntitlement/469

Fusion 360

Fusion 360 is free for personal/hobbyist use, and has also been used to create things on the CNC router at Protospace. Be sure to select the Mach3Mill postprocessor and be extremely careful about setting your work coordinate system.

Quick start guide for running a job

Startup

- Login to the computer using your personal Protospace username and password

- Power on the machine (black box under the table by the PC) and run Mach3. The controller may take a couple minutes to boot up.

- Disable the soft E-stop. If it doesn’t clear, check the mechanical E-stops

- Click

Reference Allso the machine can figure out where it is. If the machine doesn’t move, check that it’s not at any limit switches. Push it off the limit switch towards center a little and try again. Don't push it far, as this can overheat the servos! - Set up your workpiece

- Install your tool

Zerothe Z axis using a piece of paper and ‘INCR” jog mode, or the Z-probe touch-off block. (TheProbe Zbutton in Mach3 will automatically switch to tool 99, and then back to the previously-selected tool.[1] ) Make sure you set the Z zero to the same height as you set up in your design - usually the top or bottom of your model/stock.

- Move the machine to the XY datum, 0, or ‘home’ position of your job, and

Zerothe X and Y axes. - (Optional) While your project may be designed in metric units, it is far easier and safer to simply export the gcode in imperial inches, which are the default units in Mach3. If you really want to run your gcode in metric, issue command

G21in the MDI box. G21 should then show up in theMODE:line next to the E-stop button.

New / Untested Programs

| Take some precautions! |

- You can simulate the file at ncviewer.com.

- A good practice is to run untested gcode with a very high z-offset, well above your workpiece. This is called an "air cut" and will let you see what the machine will do before it is lowered to cutting height.

- You can also turn on SINGLE LINE mode. In single line mode, clicking RUN (green play icon) will run only one line of code at a time. Gcode files have a few lines of header information, so it will take a few steps before the spindle starts up and moves to the first operation.

- Keep a hand near the e-stop, just in case!

Running Your Program

- Load your g-code file. It should show your job in the display.

- Check the min/max values to see if they are reasonable. (inch/mm)

- Attach the dust boot and turn on the dust collector.

- Click

RUN.

Other Details

Dust collection: Dedicated dust collection, separate from main woodshop dust collector.

Probing: A 1/4" thick electronic touch-off plate is available on the machine, and prebuilt in Mach 3 as tool 99, with an offset of 0.250 inches.

Suitable stock materials: Wood, plastics, foams, other.

Unsuitable stock materials: Zero metal, metal alloy, or metal composites are to be cut on this machine

Work Holding

The current work surface was made from a single 5' x 12' sheet of 11/16" MDF, cut into two 5' x 5' squares. (Sourced from McKillican where Eric Coyle has a commercial account.)

It has been surfaced a few times and overall it is a fairly level plane in reference to the spindle - your mileage may vary if the spindle is out of tram or if your work holding method introduces other sources of variation.

The hold down bolts have been shortened to allow deeper surfacing passes.[1]

Through Cuts

It is considered unexcellent to cut grooves into the work surface board. If you need to make through cuts, they are best done further away from Y=0, that is father from the operator station. If you set your work origin, offsets, and tool heights carefully in the Z-Axis you will be able to make through cuts that just barely graze the top of the work surface.

Even better, and especially for small jobs (< 2' x 2') it is strongly recommended that you use your own sacrificial spoilboard, and fasten down on top off the existing T-nut grid. This can be also be a great option for creating jigs and repeatable setups. (You could add 1/4" dowel pins as precisely-positioned alignment pegs!) Small project-sized panels of MDF can be purchased rather inexpensively for this purpose.

T-nut Grid

The hold-down table has a grid of 1/4-20 threaded T-Nuts that can be used to hold down your material. The grid has unusual spacing as the T-channels in the underlying bed are reportedly aligned to Chinese inches.

The T-Nuts can be damaged by either over-tightening them, or by pulling them off vertical. Please do not be too aggressive.

The spoilboard was apparently originally cut based on hole spacing of 123.63mm on both the X and Y axis.[2] A training slide says X:122.8 Y 123.6.

However, neither of these numbers are accurate. The spacing is not the same in both axes as measured by the CNC's own coordinate system. The numbers from the training side are closest, but not perfect. The errors are small enough that you'll still see fitment issues on larger/longer patterns with 1/4" diameter holes.)

Hold down Methods

An assortment of 1/4"-20 threaded bolts, thick fender washers, wood clamps and wood blocks are available in the drawers at the machine.

Nylon bolts are a great option to consider, as this will avoid damage to the machine or to the cutting tools in case the spindle crashes the bit into a bolt (another reason to do an air cut first!) or if your work-holding hardware escapes during an aggressive cut and crashes itself into the bit!

Machine Procedures

Leveling the bed

Change Z Probe Speed

Slated Improvements

Replace current fixture board with a fixture + spoilboard

Motion Configuration

| Model | Description | Purpose / Role | |

|---|---|---|---|

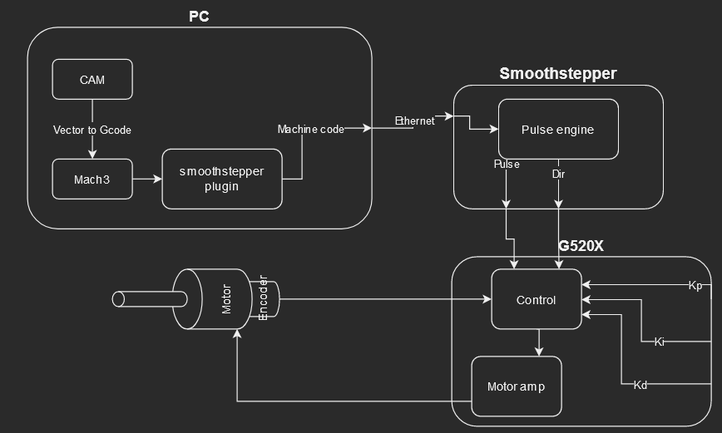

| C25XP | Ethernet Smooth Stepper Integrated Board | Mach3 Speaks to this card over ethernet protocol. This board sends the step/dir commands to the servo drivers on each axis, monitors the E-Stop loop, receives inputs from the homing limit switches, and also powers the "enable" pin. | |

| Original Precix Power Supply | |||

| Original Precix Rack and Pinion Gantry | |||

| SSR | The solid state relay is controlled by the ESD loop (e-stop loop). When the e-stop loop is broken, the SSR ensures that no power goes to the main PSU which makes it so none of the motor drivers receive power. |

Spindle

| Automation Direct

GS21-23P0 |

Variable Frequency Drive (VFD) for Spindle

(240V, 2.2 kW, 3HP) |

The VFD providers power to the spindle

Mach3 speaks to the VFD using Modbus via an RS-485 card, configured in Mach3 to communicate via a dedicated "Brain". So far, we have not been successful at receiving messages back over Modbus (e.g. true spindle RPM).[3] |

| AT/MT1073-140 | Spindle | The Z-axis has a brake to prevent the spindle from dropping on power loss, but it was removed / disabled in October 2021. [4] |

Each Axis (XYZ)

| AMT-103V | Incremental Rotary Encoder | In a true closed loop CNC system the step generator (the CNC application) gets direct feedback from the rotary encoders.

In our setup, Mach3 sends pulses to the a servo driver which moves each servo while monitoring the axis' reported movement via direct feedback from the rotary encoder, at a resolution of 128ppr (x4 = 512). [5] That part of the system is “closed loop”. However, Mach3 doesn’t know if the servo kept up or not and if the machine is in the expected position. The servo driver knows if it went as far as it was commanded, but if the discrepancy gets too large, all it can do is raise an error signal or shut down the driver. When this happens, the "machine" no longer knows where it is and must be rehomed (Ref All) to the limit switches. |

|

| Gecko G320X | Digital Servo Driver | ||

| CGS103U075V4C | Capacitor | ||

| V7-2B17D8-201 | Limit Switches | One limit switch on each axis is used to find "home". Another limit switch at each end of each axis tells the CNC drives to "shut down, you've gone too far!" (see Troubleshooting, below) | |

| Rectifier | |||

| MOV | |||

| Toroidal Transformer | |||

| Servomotor |

Troubleshooting

"Logon method is not allowed on this computer" when trying to sign in to the computer with your Protospace username and password

Your account is not authorized/enabled to use this machine, have you taken the training? Did you pay for, attend on time and pass/participate in the training? Were you vetted at the time that you took your training? Did the instructor mark you as Attended? Please verify your training records on Spaceport and check in on the forums to update your account. Also, check the network cable is fully inserted on the PC, the clip on the cable doesn't hold in the network card and the PC may not be on the network and therefore not receive access updates after training, push in to fix,

"ESS did not respond to wakeup message" Dialog box appears when starting Mach3.

This usually means the large black controller box for the machine is turned off, or did not have enough time to start before starting Mach3.

"The ESS has an invalid bootloader signature" Dialog box appears when starting Mach3.

This happens when Mach3 didn't shut down the controller correctly. Power off the controller, wait some time, power on, launch mach3 again. This can happen if someone is logged in with mach3 running in the background, comms are impossible, and a reboot has to be used.

Spindle refuses to spin

VFD (Variable Frequency Drive motor driver - big controller box near the floor on the South side (+X) of the machine)

Green light -> Power. Switch is on small box beside the controller box. Circuit breaker is on the East wall labelled Precix.

Red light -> Drive fault. Press the light/button to reset.

Sometimes the serial port on the PC gets into a weird state and comms are lost to the drive. A full power off, power on reset of the PC is needed to clear this problem.

Mach3 errors, gantry refuses to home/move

Power is on and e-stops are out?

Is it resting on the limit switches? Maybe click the limit switches in case they're stuck?

Did someone not log out properly and Mach3 has the port locked under another user? Try rebooting the PC.

Trying to use the Z probe and the machine dive-crashes into the table at 100mph

Well, don't do that. Something about the probe screen/script being lame and leaving the machine in the wrong units, from step 6 in quick start above:

6) Zero the Z axis using a piece of paper and ‘INCR” jog mode, or Z-PROBE. If using Z probe, first check probe speeds and distances in the probing screen.

Ethernet SmoothStepper ran out of data in the middle of a move

Briefly, run your file from the hard drive, and when your job is running don't mess with the computer.

- Best Practices

- Make sure your GCode is running from the hard drive. Never run GCode from a network drive or a USB stick, at some point, there will be a pause while trying to access the data and the ESS will run out of data!

- Don't switch screens or applications while running GCode

- Try not to zoom, pan / orbit the view port (3D preview) while code is running

- Don't refresh your tool path while running GCode

- Close all other software when running Mach3 (so they won't consume RAM or CPU time)

- Advanced Options (consult with the Protospace local Precix experts before changing hardware/firmware settings)

- Replace platter HDDs with SSDs

- Run Mach3 at a higher priority level. This is done in the SCU's Windows Performance Tuning

- Make sure that the Controller Frequency is set to a reasonable value.

- Warp9 reports that electronic noise or ground loops from the dust collection or VFD may cause issues

- Do an air cut and check how hard the CPU and RAM are working. If the computer is struggling, pitch an upgrade on the forum!

For more details: https://warp9td.com/index.php/faq/faq-mach3#MachThreeControllerFreq

The machine has lost its way

The driver/encoders can lose sync with Mach3 under the following conditions:[6]

- Mechanical Backlash (root cause is hardware)

- Incorrectly configured Software Backlash Compensation settings

- Pressing the physical E-Stop button while motion is in progress

- Pressing the Mach software

Stopbutton while motion is in progress - Improperly tuned acceleration or velocity settings that cause slippage on an axis

- Power was removed from the motor drivers, and the axes drifted or moved from their set position

Spindle won't reach all the way down to the table

Someone removed the 6 screws that hold the spindle motor plate to the Z axis and raised it 2 inches. Move it back down.

You can help expand this list by hopefully not breaking the Precix too badly!

:D

Maintenance

- deep clean yearly

- [add more]

Machine History

The Precix CNC was originally pitched by Scott Y. on Feb 7th, 2020. It's purchase for the spaced was voted on during the Feb 20th, 2020 meeting. The machine arrived at Protospace on Mar 26th, 2020.

Over the summer the machine was idle due to the 2020 COVID-19 Pandemic.

During this time Members Connor G. , Danny P. and Zachary J. started to work though the machine and evaluate it's condition and begin it's acceptance work. This work is documented on the admin google group post "CNC router planning/build thread", authored by Zachary J.

Going though the machine it was found that the X and Y motors were both burned out and had to be replaced. The encoders on all axis were replaced and the motor drivers were also all replaced. The controller computer, and interface cards were also replaced at this time due to poor/wanting/or no documentation on parts or interfaces.

On May 8th 2021 the CNC made it's first official project, a 4' x 5' art piece that was hanging in Protospace until July 2024.

The controller was changed in Aug due to the Galil DMC-1803 card not wanting to register in the system. We have moved to a Smoothstep board with a C25XP integrated card mounted to it.

References

- ↑ https://forum.protospace.ca/t/eliminating-tool-99-change-for-z-probe-on-precix/7142/6

- ↑ https://forum.protospace.ca/t/cnc-router-mounting-board-spacing/748/6

- ↑ https://forum.protospace.ca/t/wood-cnc-precix-help/3389/23

- ↑ https://forum.protospace.ca/t/cnc-router-acting-funny/243/34

- ↑ https://forum.protospace.ca/t/cnc-router-acting-funny/243/29

- ↑ https://warp9td.com/index.php/faq/faq-mach3#DROs