CNC router, wood (Precix) ID:153: Difference between revisions

(→Machine Overview: axis) |

No edit summary |

||

| Line 88: | Line 88: | ||

'''Unsuitable stock materials''': '''Zero''' metal, metal alloy, or metal composites are to be cut on this machine | '''Unsuitable stock materials''': '''Zero''' metal, metal alloy, or metal composites are to be cut on this machine | ||

<br /> | |||

<hr> | === Machine Procedures === | ||

[https://forum.protospace.ca/t/precix-fixture-plate-spoil-design-revision/1391/70 Leveling the bed]<br />[https://forum.protospace.ca/t/mach3-control-screen/1517 Change Z Probe Speed] | |||

=== Slated Improvements === | |||

Cut a new dust boot | |||

[https://forum.protospace.ca/t/precix-fixture-plate-spoil-design-revision/1391 Replace current fixture board with a fixture + spoilboard]<hr> | |||

===Machine history=== | ===Machine history=== | ||

| Line 108: | Line 114: | ||

Motion config (As of Aug 29/21) is as follows | Motion config (As of Aug 29/21) is as follows | ||

Training is available via the [https://my.protospace.ca/courses/428 Basic CNC Wood Rotuer course]<br /> | |||

<br /> | |||

Revision as of 03:37, 2 May 2022

| [[File:|250px]] | |

| Type | Precix Wood CNC |

| Make/Model | Industrial |

| Serial number | {{{serial}}} |

| Original owner | Protospace |

| Loan status | Current |

| Arrival date | Mar 26th, 2020 |

| Location | Wood Shop |

| Functional status | Waiting for training material |

| Usage permissions | Members |

| Certification | Required |

| Wiki-ID | 153 |

| Label | 1.0" 1.5" 2.0" |

Training and Documentation

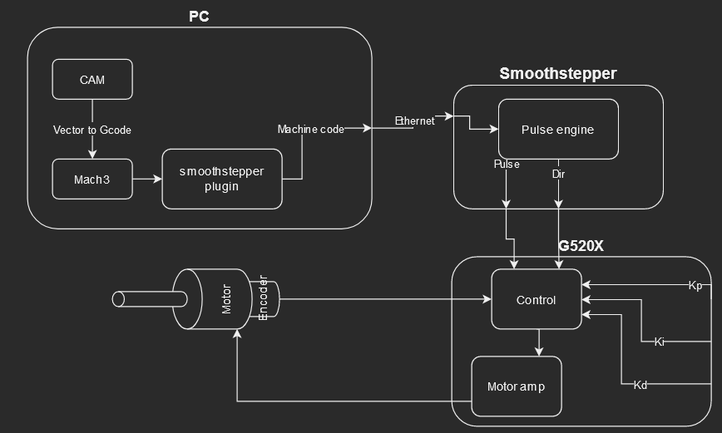

The Precix PC uses Mach3 to control the CNC. It also has a Makerspace licensed version of VCarve Pro installed which you can use in conjunction with the Client you are going to install as per the instructions below.

VCarve

Note: You can install and run VCarve Pro Makerspace Client Edition on your home PC or Laptop. This allows you to create VCarve files that you can then bring in to Protospace and create G-Code files on the licensed workstations in the space.

![]() For Instructions for installing, licensing, and Using VCarve Pro Makerspace Client click here.

For Instructions for installing, licensing, and Using VCarve Pro Makerspace Client click here.

MACH3

Mach3 has an optimized, custom screen set installed, although if you wish, you can change it back to the traditional screen. Just remember to return it to the custom set when you are finished.

Links to HOW TO Videos:

- MACH Support YouTube Channel

- "MACH3 Has Never Looked This Good." Video explaining our Mach3 Custom Interface that is installed on the Precix PC

Hold down method

The hold-down table has a grid of threaded T-Nuts that can/should be used to hold down your material. If you wish to make your own sacrificial / holding system, simply prepare to fasten it down to this grid pattern. Use the 1/3-20 screws (or bolts if you are gentle).

The spacing of the threaded nuts is 4.861" (123.63mm) on both the X and also Y axis. Wtf is that spacing? Why not a nice round English or Metric spacing? Well, that is the spacing of the T-channels in the underlying bed. Get used to it and make your templates.

The T-Nuts can be damaged by either over-tightening them, or by pulling them off vertical. Please be smart and not too aggressive.

Machine Overview

Bed size: 5'(1.524m) x 10'(3.048m) x 11"(0.2794m)

Axis Orientation: Y is the long one.

Max spindle RPM: 18000RPM (spindle is a AT/MT1073-140 from HSD mechatronics)

Spindle power: 2.2KW, 3HP Spindle type: VFD based motor. (VFD is a commander SK from control tech user manual, advance user manual)

Max feed rate: 750inch/min

Tool holder type: ER25 collets, we have 1/8", 1/4",3/8",1/2" (as of 05.11.2021)

Automatic tool changer: No

File units: Default units are imperial. you may switch to metric using gcode commands, it is recommended that you export imperial code.

File type accepted: .tap, .gcode, .txt

Machine control software suite: Mach3 skinned with physics anonymous Mach pack

Will do 3 axis moves?:Yes

Hold down method: Screws, nails, clamps(must make these). Vacuum table in the future.

Note that the hold-down table has a grid of threaded T-Nuts that can/should be used to hold down your material. If you wish to make your own sacrificial / holding system, simply prepare to fasten it down to this grid pattern. The spacing of the threaded nuts is 4.861" (123.63mm) on both the X and also Y axis. Wtf is that spacing? Why not a nice round English or Metric spacing? Well, that is the spacing of the T-channels in the underlying bed. Get used to it and make your templates.

Dust collection?: Yes, separate from main dust collector

Probing: plate style. Plate is 1/4" (as of 06.01.2021) thick.

Suitable stock materials: Wood, plastics, foams, other.

Unsuitable stock materials: Zero metal, metal alloy, or metal composites are to be cut on this machine

Machine Procedures

Leveling the bed

Change Z Probe Speed

Slated Improvements

Cut a new dust boot

Replace current fixture board with a fixture + spoilboard

Machine history

The Precix CNC was originally pitched by Scott Y. on Feb 7th, 2020. It's purchase for the spaced was voted on during the Feb 20th, 2020 meeting.

The machine arrived at Protospace on Mar 26th, 2020.

Over the summer the machine was idle due to the 2020 COVID-19 Pandemic.

During this time Members Connor G. , Danny P. and Zachary J. started to work though the machine and evaluate it's condition and begin it's acceptance work. This work is documented on the admin google group post "CNC router planning/build thread", authored by Zachary J.

Going though the machine it was found that the X and Y motors were both burned out and had to be replaced. The encoders on all axis were replaced and the motor drivers were also all replaced. The controller computer, and interface cards were also replaced at this time due to poor/wanting/or no documentation on parts or interfaces.

On May 8th 2021 the CNC made it's first official project, a 4' x 5' art piece that is hanging somewhere in Protospace (can you find it?).

The controller was changed in Aug due to the Galil DMC-1803 card not wanting to register in the system. We have moved to a Smoothstep board with a C25XP integrated card mounted to it.

Motion config (As of Aug 29/21) is as follows

Training is available via the Basic CNC Wood Rotuer course