3D printer, resin (Anycubic Photon 5.5) ID:159: Difference between revisions

Jump to navigation

Jump to search

Parker.link (talk | contribs) m (→Your First Print: Add gloves to procedure) |

Parker.link (talk | contribs) m (Fix headings) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 16: | Line 16: | ||

This printer is an Anycubic Photon 5.5. Note that it has undergone an upgrade, making it more similar to the ELEGOO MARS 2 PRO (useful for slicing). | This printer is an Anycubic Photon 5.5. Note that it has undergone an upgrade, making it more similar to the ELEGOO MARS 2 PRO (useful for slicing). | ||

== Specs == | |||

Resolution/Build Size: | Resolution/Build Size: | ||

| Line 22: | Line 23: | ||

*Z: 160mm | *Z: 160mm | ||

== | ==Documentation== | ||

[https://www.anycubic.com/products/anycubic-photon-3d-printer Product Page] | [https://www.anycubic.com/products/anycubic-photon-3d-printer Product Page] | ||

| Line 28: | Line 29: | ||

[https://wiki.protospace.ca/images/6/60/NL-POT011-C_ANYCUBIC_Photon-english-20190906-V13.pdf Manual] | [https://wiki.protospace.ca/images/6/60/NL-POT011-C_ANYCUBIC_Photon-english-20190906-V13.pdf Manual] | ||

== | ==Usage== | ||

No training is required for this printer. Get someone to walk you through the process, and then you can print using it. | No training is required for this printer. Get someone to walk you through the process, and then you can print using it. | ||

| Line 52: | Line 53: | ||

#Start the print. | #Start the print. | ||

#Listen to ensure that 30 seconds after the print starts, you hear a popping noise as the print separates from the clear plastic sheet and stays attached to the blue build plate. Cancel the print if you don't hear the popping noise, probably. | #Listen to ensure that 30 seconds after the print starts, you hear a popping noise as the print separates from the clear plastic sheet and stays attached to the blue build plate. Cancel the print if you don't hear the popping noise, probably. | ||

# | #You can estimate the print time based on the Duration and Percent Complete. | ||

#When complete, use the [[Curing station (Anycubic Wash and Cure Machine) ID:160|Curing station]] guide/video to post-process, clean, and cure your print. | |||

#Drain the excess resin in the tray back into the bottle. Avoid contamination. Use a squeegee, and don't break the clear plastic sheet. | |||

#Wipe down with IPA. | |||

==Discussion Threads== | ==Discussion Threads== | ||

[https://forum.protospace.ca/t/resin-printers-down/688 Resin Printers Down] | [https://forum.protospace.ca/t/resin-printers-down/688 Resin Printers Down] | ||

Latest revision as of 04:39, 23 February 2023

← Back to tools we have

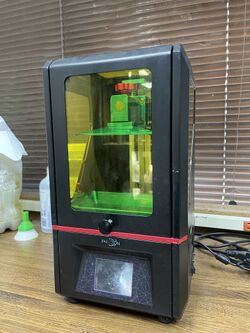

Anycubic Photon 5.5 Resin Printer | |

| Type | Anycubic Photon 5.5 Resin Printer |

| Make/Model | Photon 5.5 |

| Serial number | 00340019-30384717-36333332-71 |

| Original owner | ?? |

| Loan status | ?? |

| Arrival date | ?? |

| Location | 3D Printer Village |

| Functional status | Functional |

| Usage permissions | ?? |

| Certification | ?? |

| Wiki-ID | 159 |

| Label | 1.0" 1.5" 2.0" |

This resin printer is the smaller of two resin printers at Protospace. Resin printers are ideal for 3D printing very fine details, but take a bit of extra effort (compared to their FDM counterparts).

This printer is an Anycubic Photon 5.5. Note that it has undergone an upgrade, making it more similar to the ELEGOO MARS 2 PRO (useful for slicing).

Specs

Resolution/Build Size:

- X: 1620px (82.62mm)

- Y: 2560px (130.56mm)

- Z: 160mm

Documentation

Usage

No training is required for this printer. Get someone to walk you through the process, and then you can print using it.

Included here is a step-by-step guide of how to use this 3D printer well.

- Turn on the power bar above the printer. Ensure the heated enclosure also turns on and is set to 25C-30C.

- Slice your file on the computer using the Chitubox program.

- Go to "Settings" on the right side.

- Select the "Chitusystems Mono Upgrade" machine on the far-left.

- Select the "... BASELINE ..." profile at the top.

- Duplicate the profile if you intend to make changes to it. Include your name and project name.

- Make changes to setting as desired. Large non-hollow objects may need more lowering time and curing time. Layer heights can be changed as well.

- Avoid creating suction-cup inclusions by using the Remove Hole button to remove holes along the build plate of the model. You can also redesign your model, or rotate your model to avoid this phenomenon.

- Add supports as required.

- Save to a USB stick.

- Don gloves. The resin washes off pretty well with soap, but you'll wanna wear gloves.

- Clean the clear plate/resivoir that goes atop the LCD using IPA. Be careful not to puncture it with your paper towel (??).

- Install the clear plate on the printer and tighten the screws.

- Clean the build plate with IPA. Install it on the printer. Tighten the screw.

- Optionally level the build plate (TODO write instructions for this).

- Insert the USB stick into the right side of the printer.

- Use the screen to go to Print, and select your file. If you saved the file right, you should see a blue preview of your model.

- Start the print.

- Listen to ensure that 30 seconds after the print starts, you hear a popping noise as the print separates from the clear plastic sheet and stays attached to the blue build plate. Cancel the print if you don't hear the popping noise, probably.

- You can estimate the print time based on the Duration and Percent Complete.

- When complete, use the Curing station guide/video to post-process, clean, and cure your print.

- Drain the excess resin in the tray back into the bottle. Avoid contamination. Use a squeegee, and don't break the clear plastic sheet.

- Wipe down with IPA.