Laser cutter (Trotec Speedy 300) ID:107: Difference between revisions

m (Cjs moved page Laser cutter, TroTec ID:107 to Laser cutter (TroTec) ID:107) |

Pat.spencer (talk | contribs) (→Maintenance: Added text and pictures referring to Dust Collector cleaning) |

||

| (65 intermediate revisions by 10 users not shown) | |||

| Line 1: | Line 1: | ||

{{Equipment page | {{Equipment page | ||

| toolname = | | toolname = Trotec | ||

| model = [https://www.troteclaser.com/en-ca/laser-machines/laser-engravers-speedy-series/ Speedy 300] | |||

| model = [https://www.troteclaser.com/en-ca/laser-machines/laser-engravers-speedy-series/ | |||

| serial = S3-4699 | | serial = S3-4699 | ||

| owner = Protospace | | owner = Protospace | ||

| loanstatus = Owned by Protospace | | loanstatus = Owned by Protospace | ||

| arrived = | | arrived = December 2016 | ||

| location = Bay 108, near the door to the front rooms | | location = Bay 108, near the door to the front rooms | ||

| status = Working | |||

| permission = Members & Friends Only | | permission = Members & Friends Only | ||

| certification = Must complete [[Laser Certification]] | | certification = Must complete [[Laser Certification]] and [[Trotec Certification]] | ||

| id = 107 | | id = 107 | ||

}} | }} | ||

==Quick Specs== | |||

*'''Working bed size:''' 730mm x 430mm (28 3/4" x 17" ish) | |||

*'''Engraving resolution:''' 1000DPI | |||

*'''Kerf:''' 0.1mm | |||

*'''Supported file formats:''' Anything that can be "printed" to [https://www.troteclaser.com/en-ca/laser-machines/jobcontrol JobControl] with the appropriate vectors, fills and line formatting. Trotec's [https://www.youtube.com/c/TrotecLaserCanada/videos excellent tutorials] and our [https://docs.google.com/presentation/d/1_RdW1xh5ltwHSCs7e7BQaaY60jo0sO8frpAQ2GgcG5w/edit?usp=sharing training courses] are done in [https://www.coreldraw.com/en/ CorelDRAW], so the computer attached to our laser provides a licensed copy. Other popular software includes [https://inkscape.org/ Inkscape], [https://www.autodesk.ca/en/products/autocad/overview Autodesk AutoCAD] and [https://www.adobe.com/ca/products/illustrator.html Adobe Illustrator], generating files such as DXF, CDR, SVG, AI, PDF, etc. | |||

*'''Maximum material thickness:''' generally 1/2", with thicker materials possible using multiple passes, resulting in poor edge finish due to kerf. | |||

<br /> | |||

==Usage and Billing Policies== | |||

{{Money|This tool is not free.}} | |||

All members [https://my.protospace.ca/courses/321 certified] on the Trotec receive six hours per month of free laser use. Additional time is billed at $0.50 per minute. This is "laser on" or tube time, as tracked by the tablet mounted on the wall above the Trotec. Users are responsible for monitoring their own usage and making payment accordingly. | |||

This section is under development. If you have concerns regarding commercial or "excessive" use, reach out to laser trainers, forums, directors, etc. | |||

Agreement is under review but included for reference. | |||

*[https://drive.google.com/file/d/0By-vvp6fxFekUF9WZG9jaFdwMHc/view?resourcekey=0-GxIydSgSjerHfn-1onI0gw Trotec Laser Account Agreement] | |||

Additionally, users must perform the necessary maintenance, including inspecting the lens and mirror, and cleaning if necessary<br /> | |||

==Documentation== | |||

{{Warning|It is imperative to <u>complete a [[chlorine test]] on materials</u> before working with them in any laser cutter.}} | |||

{{Warning|Per training and usage agreement, <u>the lens and mirror must be checked and cleaned:</u> | |||

* before use | |||

* hourly during continuous use | |||

* when used with unfamiliar material | |||

* after use.}} | |||

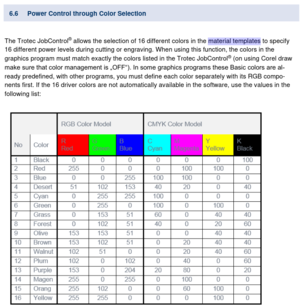

[[File:Power Control through Color Selection Table.png|thumb|Power Control through Color Selection Table from the JobControl 11.2 Manual]] | |||

======References====== | |||

[https://docs.google.com/presentation/d/1_RdW1xh5ltwHSCs7e7BQaaY60jo0sO8frpAQ2GgcG5w/edit?usp=sharing Trotec Training] | |||

[https://drive.google.com/drive/folders/0B4igHgxabriCeGI1OWlTOV90dWs?resourcekey=0-BmjyVLbDcki46YPtgD4tFw&usp=sharing Google Drive: Trotec documentation resources] | |||

[https://www.youtube.com/c/TrotecLaserCanada/videos YouTube: Trotec Laser Canada] | |||

[https://wiki.protospace.ca/images/e/ef/Speedy-300-Manual-EN.pdf Speedy 300 Product Manual] | |||

[https://wiki.protospace.ca/images/a/a4/JobControl-11-2-operation-manual-EN.pdf JobControl 11.2 Operation Manual] | |||

======Tips and tricks====== | |||

Engraving can be done with image files (PNG et al) including photo engraves, or with vector fills, including masking with white. | |||

Please try any new, strange, or unknown materials in the Rabbit first, and closely watch them for flame or dense black smoke. | |||

The lens is very exposed on the Trotec and thick smokey materials, like woods full of resin or glue, rubber, or some plastics, can very quickly damage the machine and potentially the lungs of everyone in the space. | |||

Start with low power tests and work your way up. | |||

<br /> | |||

======Power and speed settings====== | |||

[[File:Speedy300-80W-MarkSolid.pdf|thumb|Trotec Speedy 300 Material Parameters]] | |||

<br /> | |||

======Permissions on TROTEC PC to install software/fonts====== | |||

Occasionally we get requests from a member who wants to do something on the Trotec PC which requires elevated privileges.<br> | |||

The normal permissions are that users do not have Local Admin rights so that we can limit the rogue changes to the system. We HAVE put in place a procedure that someone can request to be elevated temporarily so that a knowledgable user can perform installs etc. <br> | |||

The procedure is to contact one of the Network/System Administrators and request that you be added to the "Laser-Trotec-Admins" group. <br> | |||

Until we come up with an improved the procedure, please send a message to @pat.spencr on SpacePort, or email me directly @protospace.ca | |||

==Troubleshooting== | |||

======Laser won't move side to side or up and down====== | |||

Lid must be closed on startup to allow the platform to home to the base. | |||

======"Logon method is not allowed on this computer" when trying to sign in to the computer with your Protospace username and password====== | |||

Your account is not authorized/enabled to use this machine, have you taken the training? Did you pay for, attend on time and pass/participate in the training? Were you vetted at the time that you took your training? Did the instructor mark you as Attended? Please verify your training records on Spaceport and check in on the forums to update your account. | |||

======CorelDRAW won't launch (shows logo and immediately quits, doesn't get to login screen)====== | |||

In Windows, navigate to C:\Users\Your.Username\AppData\Roaming\ (replace "Your.Username" with the name used to logon to the machine; note that the "AppData" folder is hidden, and will need to be manually typed into the address bar). Rename the "Corel" folder to "Corel.bak" and attempt to launch CorelDRAW. This process will displace your tool presets, window positions, recent files list, palettes, etc. | |||

======CorelDRAW login shows "Error: Unknown Error", or is otherwise corrupt or drawn weird====== | |||

The profile reset process above for "CorelDRAW won't launch" seemed to fix the error. If the login window isn't rendering properly, the Tab key on the keyboard can be used to navigate between fields and off-screen buttons... | |||

======Lines are not picked up by JobControl====== | |||

See color chart on this page, verify your palette. Check line thickness, it should be "hairline" or very small, 0.2px seemed to work in Inkscape. | |||

Ensure alpha/transparency is set to full opaqueness, be that 0% or 100% in the software of your choosing - especially Inkscape. | |||

In your material settings, is the chosen color assigned to a function such as cut, engrave, position, etc?? | |||

======JobControl shows a 0:00 estimate, even with valid lines/colors====== | |||

With short cuts (<15sec?), sometimes the estimated time shown will be 0:00 after updating job time. If the color is being picked up by JobControl and the lines appear correct in preview, just try it - scrap material is helpful here. | |||

======Printing to JobControl shows a blank job====== | |||

Fix page size in editor's Page Setup and/or Trotec Engraver printer preferences Job Size. Try moving work to another part of the page; check Print Preview and CorelDRAW's Preflight tab. | |||

======Error "No jobs for transmission found"====== | |||

Right click the job and press reset. | |||

======JobControl says that "job will not fit on plate"====== | |||

When printing, venture into the Trotec Engraver printer settings, under the "Preferences" button and ensure that both "Take from application" and "Minimize to jobsize" are enabled. If these options are not showing, enable them under the "General" tab and change the view to "Expert". Then, ensure that your job actually fits onto a page that'll fit on the Trotec bed. Watch for stragglers, points of vectors, errant pastes or lines. Check the Print Preview and CorelDRAW's Preflight tab. Move your work to another part of the page. If all else fails, return to the Trotec Engraver printer settings and manually set the jobsize to equal the Trotec bed size. | |||

======Job appears to print successfully, but doesn't show in JobControl's queue====== | |||

*Disable DPI filter below list on the right in JobControl | |||

*Open the [https://www.techsupportall.com/solved-how-to-clean-printer-spool-queue-clean-print-spool-fixit/ Windows printer queue] by double clicking the printer icon on the right side of the task bar, then right click on each job and Cancel. (Reference: [https://forum.protospace.ca/t/trotec-cant-talk-to-computer/3205/28?u=gregm Trotec "printer" permissions have been updated] and this should now work for all users) | |||

*Restart the computer | |||

======"No response from engraver" or other COM port issue====== | |||

Someone may have left themselves logged in, try restarting the machine to release the port. | |||

======Trotec Rotary Not Working / Connection====== | |||

The fix was replacing a fuse in the fuse box, but the cause of the blown fuse is less obvious | |||

The molex connector wasn’t connected properly on the rotary’s end. One of the pins was wedged up toward the top. I think the fuse blew when I tried to use it. I had to tweeze the connector back to proper shape. | |||

Extra replacement fuses are in the drawer, but it’s going good now. | |||

This is as good a place as any to say be VERY careful when plugging in the molex connector, the machine has to be '''''off''''' and if it fights you at all it is in the wrong way. Inspect the cable and see which side the little clippy thing has broken off, and line it up to the little clippy thing on the port. | |||

Also, when carrying the rotary out of the classroom (carpet) be sure you are only touching the metal parts, not the inexplicably-exposed pcb at the bottom, as ESD is common for that reason per the technician. | |||

======Unable to add a new materials group====== | |||

Scroll all the way to bottom and right-click the whitespace below Zac's name. Then select "Create group". | |||

======Anything else====== | |||

https://forum.protospace.ca/c/areas/laser-beams/13 | |||

[mailto:REMOVE_laser_FURSPAM@protospace.ca Email contact instructions] | |||

[[File:320px-HelloIT.jpg|alt=]] | |||

<br /> | |||

==Maintenance== | |||

Major problems are best reported by [mailto:REMOVE_laser_FURSPAM@protospace.ca Email contact instructions] and left to TroCare warranty by local technician, but preventative maintenance is our responsibility, per tech: | |||

As needed: Clean lens and first mirror. Inspect both after every hour of laser-on time, and clean any visible residue | |||

Monthly: Clean linear rails for x and y axis, using 3M silicone lubricant and a clean cotton rag or soft paper towel. Move the carriage gently by hand to clean underneath it. | |||

Yearly? - Clean dust collection chamber and vacuum hose. See pictures of dust. [[:File:107-Trotec-20240730.jpg]] and [[:File:107-Trotec-20240730-2.jpg]] | |||

[https://www.youtube.com/watch?v=Fguib-8X1RI Trotec Laser Canada - How to Properly Clean and Maintain Your Trotec Speedy 300 Laser Cutting Machine] | |||

==History== | |||

July-2024 - Another fire occurred ([https://forum.protospace.ca/t/fire-while-using-the-trotec/7130 forum post]). This time due to combustible build up in a (seemingly) hard to reach area | |||

June 2023 - material caught fire in the Trotec ([https://forum.protospace.ca/t/trotec-out-of-order/4126 forum post]). Trotec completed all necessary repairs (energy chain and air assist, x axis belt, dust protection belt, top cover/lid, x axis limit switch, laser pointer). The work bed was also replaced at this time (unrelated to the fire). Trotec tech tested laser output (91.1W). | |||

Feb 2023 - [[Trotec-PC-Disk-Upgrade|Trotec PC Disk Drive upgrade]]. The Trotec PC started exhibiting OS Stability issues, primarily the Print Spooler crashing. The disk was nearly full. | |||

Sept 2022 - [https://forum.protospace.ca/t/trotec-problems/2051 second replacement and repair of Y motor] by Trotec technician, [https://forum.protospace.ca/t/late-entry-motion-trotec-repair-budget/2402 purchase of TroCare warranty] | |||

Aug/Sept 2020 - [https://groups.google.com/u/2/g/protospace-administration/c/hnP4H-rPB2Y/m/Lk8UM0QUAgAJ replacement and repair of Y motor] | |||

June 30th 2019 - [https://groups.google.com/u/2/g/protospace-discuss/c/BKWTS6N_0a0/m/mjBBmakQAwAJ first aftermarket replacement lens installed] | |||

June 12th 2019 - [https://groups.google.com/u/2/g/protospace-discuss/c/aHkjj7tKWTw/m/FstksObLAQAJ eggcrate DIY worktable installed] | |||

December 2016 - purchased, new | |||

<br /> | |||

[[Category:Showcase tools]] | [[Category:Showcase tools]] | ||

[[Category:Plasticworking tools]] | [[Category:Plasticworking tools]] | ||

| Line 19: | Line 172: | ||

[[Category:Textileworking tools]] | [[Category:Textileworking tools]] | ||

[[Category:Computer-controlled tools]] | [[Category:Computer-controlled tools]] | ||

Latest revision as of 06:01, 31 July 2024

| |

| Type | Trotec |

| Make/Model | Speedy 300 |

| Serial number | S3-4699 |

| Original owner | Protospace |

| Loan status | Owned by Protospace |

| Arrival date | December 2016 |

| Location | Bay 108, near the door to the front rooms |

| Functional status | Working |

| Usage permissions | Members & Friends Only |

| Certification | Must complete Laser Certification and Trotec Certification |

| Wiki-ID | 107 |

| Label | 1.0" 1.5" 2.0" |

Quick Specs

- Working bed size: 730mm x 430mm (28 3/4" x 17" ish)

- Engraving resolution: 1000DPI

- Kerf: 0.1mm

- Supported file formats: Anything that can be "printed" to JobControl with the appropriate vectors, fills and line formatting. Trotec's excellent tutorials and our training courses are done in CorelDRAW, so the computer attached to our laser provides a licensed copy. Other popular software includes Inkscape, Autodesk AutoCAD and Adobe Illustrator, generating files such as DXF, CDR, SVG, AI, PDF, etc.

- Maximum material thickness: generally 1/2", with thicker materials possible using multiple passes, resulting in poor edge finish due to kerf.

Usage and Billing Policies

| This tool is not free. |

All members certified on the Trotec receive six hours per month of free laser use. Additional time is billed at $0.50 per minute. This is "laser on" or tube time, as tracked by the tablet mounted on the wall above the Trotec. Users are responsible for monitoring their own usage and making payment accordingly.

This section is under development. If you have concerns regarding commercial or "excessive" use, reach out to laser trainers, forums, directors, etc.

Agreement is under review but included for reference.

Additionally, users must perform the necessary maintenance, including inspecting the lens and mirror, and cleaning if necessary

Documentation

| It is imperative to complete a chlorine test on materials before working with them in any laser cutter. |

Per training and usage agreement, the lens and mirror must be checked and cleaned:

|

References

Google Drive: Trotec documentation resources

JobControl 11.2 Operation Manual

Tips and tricks

Engraving can be done with image files (PNG et al) including photo engraves, or with vector fills, including masking with white.

Please try any new, strange, or unknown materials in the Rabbit first, and closely watch them for flame or dense black smoke. The lens is very exposed on the Trotec and thick smokey materials, like woods full of resin or glue, rubber, or some plastics, can very quickly damage the machine and potentially the lungs of everyone in the space. Start with low power tests and work your way up.

Power and speed settings

File:Speedy300-80W-MarkSolid.pdf

Permissions on TROTEC PC to install software/fonts

Occasionally we get requests from a member who wants to do something on the Trotec PC which requires elevated privileges.

The normal permissions are that users do not have Local Admin rights so that we can limit the rogue changes to the system. We HAVE put in place a procedure that someone can request to be elevated temporarily so that a knowledgable user can perform installs etc.

The procedure is to contact one of the Network/System Administrators and request that you be added to the "Laser-Trotec-Admins" group.

Until we come up with an improved the procedure, please send a message to @pat.spencr on SpacePort, or email me directly @protospace.ca

Troubleshooting

Laser won't move side to side or up and down

Lid must be closed on startup to allow the platform to home to the base.

"Logon method is not allowed on this computer" when trying to sign in to the computer with your Protospace username and password

Your account is not authorized/enabled to use this machine, have you taken the training? Did you pay for, attend on time and pass/participate in the training? Were you vetted at the time that you took your training? Did the instructor mark you as Attended? Please verify your training records on Spaceport and check in on the forums to update your account.

CorelDRAW won't launch (shows logo and immediately quits, doesn't get to login screen)

In Windows, navigate to C:\Users\Your.Username\AppData\Roaming\ (replace "Your.Username" with the name used to logon to the machine; note that the "AppData" folder is hidden, and will need to be manually typed into the address bar). Rename the "Corel" folder to "Corel.bak" and attempt to launch CorelDRAW. This process will displace your tool presets, window positions, recent files list, palettes, etc.

CorelDRAW login shows "Error: Unknown Error", or is otherwise corrupt or drawn weird

The profile reset process above for "CorelDRAW won't launch" seemed to fix the error. If the login window isn't rendering properly, the Tab key on the keyboard can be used to navigate between fields and off-screen buttons...

Lines are not picked up by JobControl

See color chart on this page, verify your palette. Check line thickness, it should be "hairline" or very small, 0.2px seemed to work in Inkscape.

Ensure alpha/transparency is set to full opaqueness, be that 0% or 100% in the software of your choosing - especially Inkscape.

In your material settings, is the chosen color assigned to a function such as cut, engrave, position, etc??

JobControl shows a 0:00 estimate, even with valid lines/colors

With short cuts (<15sec?), sometimes the estimated time shown will be 0:00 after updating job time. If the color is being picked up by JobControl and the lines appear correct in preview, just try it - scrap material is helpful here.

Printing to JobControl shows a blank job

Fix page size in editor's Page Setup and/or Trotec Engraver printer preferences Job Size. Try moving work to another part of the page; check Print Preview and CorelDRAW's Preflight tab.

Error "No jobs for transmission found"

Right click the job and press reset.

JobControl says that "job will not fit on plate"

When printing, venture into the Trotec Engraver printer settings, under the "Preferences" button and ensure that both "Take from application" and "Minimize to jobsize" are enabled. If these options are not showing, enable them under the "General" tab and change the view to "Expert". Then, ensure that your job actually fits onto a page that'll fit on the Trotec bed. Watch for stragglers, points of vectors, errant pastes or lines. Check the Print Preview and CorelDRAW's Preflight tab. Move your work to another part of the page. If all else fails, return to the Trotec Engraver printer settings and manually set the jobsize to equal the Trotec bed size.

Job appears to print successfully, but doesn't show in JobControl's queue

- Disable DPI filter below list on the right in JobControl

- Open the Windows printer queue by double clicking the printer icon on the right side of the task bar, then right click on each job and Cancel. (Reference: Trotec "printer" permissions have been updated and this should now work for all users)

- Restart the computer

"No response from engraver" or other COM port issue

Someone may have left themselves logged in, try restarting the machine to release the port.

Trotec Rotary Not Working / Connection

The fix was replacing a fuse in the fuse box, but the cause of the blown fuse is less obvious

The molex connector wasn’t connected properly on the rotary’s end. One of the pins was wedged up toward the top. I think the fuse blew when I tried to use it. I had to tweeze the connector back to proper shape.

Extra replacement fuses are in the drawer, but it’s going good now.

This is as good a place as any to say be VERY careful when plugging in the molex connector, the machine has to be off and if it fights you at all it is in the wrong way. Inspect the cable and see which side the little clippy thing has broken off, and line it up to the little clippy thing on the port.

Also, when carrying the rotary out of the classroom (carpet) be sure you are only touching the metal parts, not the inexplicably-exposed pcb at the bottom, as ESD is common for that reason per the technician.

Unable to add a new materials group

Scroll all the way to bottom and right-click the whitespace below Zac's name. Then select "Create group".

Anything else

https://forum.protospace.ca/c/areas/laser-beams/13

Maintenance

Major problems are best reported by Email contact instructions and left to TroCare warranty by local technician, but preventative maintenance is our responsibility, per tech:

As needed: Clean lens and first mirror. Inspect both after every hour of laser-on time, and clean any visible residue

Monthly: Clean linear rails for x and y axis, using 3M silicone lubricant and a clean cotton rag or soft paper towel. Move the carriage gently by hand to clean underneath it.

Yearly? - Clean dust collection chamber and vacuum hose. See pictures of dust. File:107-Trotec-20240730.jpg and File:107-Trotec-20240730-2.jpg

History

July-2024 - Another fire occurred (forum post). This time due to combustible build up in a (seemingly) hard to reach area

June 2023 - material caught fire in the Trotec (forum post). Trotec completed all necessary repairs (energy chain and air assist, x axis belt, dust protection belt, top cover/lid, x axis limit switch, laser pointer). The work bed was also replaced at this time (unrelated to the fire). Trotec tech tested laser output (91.1W).

Feb 2023 - Trotec PC Disk Drive upgrade. The Trotec PC started exhibiting OS Stability issues, primarily the Print Spooler crashing. The disk was nearly full.

Sept 2022 - second replacement and repair of Y motor by Trotec technician, purchase of TroCare warranty

Aug/Sept 2020 - replacement and repair of Y motor

June 30th 2019 - first aftermarket replacement lens installed

June 12th 2019 - eggcrate DIY worktable installed

December 2016 - purchased, new