CNC router, benchtop (SIENCI LongMill) ID:143: Difference between revisions

Aerobatpat (talk | contribs) mNo edit summary |

Pat.spencer (talk | contribs) (→Update: (10/21/2022): Added link to Longboard Documentation on Scenci's site.) |

||

| (37 intermediate revisions by 3 users not shown) | |||

| Line 2: | Line 2: | ||

| toolname = LongMill Wood CNC | | toolname = LongMill Wood CNC | ||

| model = Industrial | | model = Industrial | ||

| owner =Protospace | | serial = N/A | ||

| loanstatus =Current | | owner = Protospace | ||

| arrived =Oct 28th, 2021 | | loanstatus = Current | ||

| arrived = Oct 28th, 2021 | |||

| location = Wood Shop | | location = Wood Shop | ||

| status = Waiting for training material | | status = Waiting for training material | ||

| certification = | | permission = Members & Friends Only | ||

| photo= | | certification = Must complete [[CNC-LongMill Certification]] | ||

| id= | | photo = LongMill-on-Shelf-01.png | ||

| id = 143 | |||

}}<br /> | }}<br /> | ||

==Update: (10/21/2022)== | |||

The LongMill has been installed on the shelf in the "Large Projects" area, along side of the MiniCNC. | |||

===Machine Overview=== | ===Machine Overview=== | ||

This is a SIENCI (pronounced "CNC") Labs LongMill ( See https://sienci.com/product/longmill/ ) with the short rails. The web page says it is 12"x12" but in fact it is more like 10"x13". | |||

The controller is an Arduino running GRBL. <br />There is a ton of valuable reference material on their "Resources" website. See -> https://resources.sienci.com/view/lm-welcome/ | |||

For technical Details see https://resources.sienci.com/view/lm-longboard-documentation/ | |||

'''Bed size''': 250mm x 340mm (10"x 13"). The Z travel is 105mm. The clearance below the gantry is also about 105mm so this is the thickest material that could be mounted, although the router can be adjusted higher if the material has the right shape to clear the gantry. There is about a 60mm offset from the gantry to the router bit (in the Y axis) that could be used for taller pieces. | |||

'''Spindle''': Makita Trim Router Model RT0701C ( https://www.makitatools.com/products/details/RT0701C). The Makita Router has a 1/4" collet, and a also a 1/8" collet insert. Manually controlled, this router has variable speed spindle from 10,000 to 30,000 RPM. It is manually controlled (Not controlled in software). There is a collection of bits in the red toolbox under the CNC. | |||

Currently, the Spindle power is not controlled by the CNC Controller and must be turned On/Off manually. This is on the list of improvements. | |||

'''Machine Control:''' GRBL on a SIENCI Milling Labs LONGBOARD Controller. | |||

'''User Interface:''' The Raspberry PI that was originally installed has been replaced with a faster and more robust "nanoPC" (model nT-A3800) connected to the Controller via USB. It has [https://resources.sienci.com/view/gs-installation/ GSender], [https://winder.github.io/ugs_website/ Universal G-Code Sender (UGCS)]as well as [https://github.com/vlachoudis/bCNC bCNC] installed. | |||

'''PC Login''': The Debian logon on is automatic on startup, so you do not need to log on. But if you need it for any reason, it is protospace/protospace. | |||

'''Hold down method''': Screws, nails, clamps(must make these). | |||

Note that the base plate mounting board is MDF but '''IS NOT A SACRIFICIAL BOARD'''. The mounting board has threaded inserts on a 10cm x 10cm grid. You can supply your own hold down board with whatever system you wish. Simply drill holes in your board so that you can mount it to these threaded inserts. The threaded inserts are 10x24. There are a sample supply of different length screws for you to use. | |||

=== | '''Dust collection?''': Yes, requires a ShopVac. | ||

The LongMill CNC was donated by Peter | |||

'''Probing''': plate style. Plate is 15mm thick as well as X and Y 10mm offset. | |||

'''Suitable stock materials''': Wood, plastics, foams, other. | |||

'''Unsuitable stock materials''': Zero metal, metal alloy, or metal composites are to be cut on this. If the CNC machine was on the rolling cart, it possibly could be moved outside to do some aluminum milling, but for now don't do it. | |||

===Instructions and Training=== | |||

<hr> | |||

====How to turn on the machine==== | |||

The main power is turned on by turning on the common power bar for the shelf. This also turns on the lights as well as power for the MiniCNC | |||

. [[File:143 PowerBar-01.png|200px|Main Power Bar Switch]] [[File:143-Powerbar-02.png|200px|LongMill power bar]] | |||

There are 2 power switches to be turned on (not counting the monitor). | |||

*The nanoPC has it's own power supply plugged into the power bar. There is a power switch on the front of the PC. | |||

*The SCENCI Longboard has a power switch. | |||

*And finally, when you want to start the Router, you also need to turn on the switch on the router. (Note: that this may be put on a more convenient switch and even maybe software control in the future. ) | |||

[[File:143-Longmill-Power-Controller.png|250px|LongMill Controller power]] [[File:143-LongMill-Pi-Power.jpg|150px|RaspberryPi Power]] [[File:143-LongMill-Makita-Router-Switches.png|200px|Makita Router Switches]] | |||

* | |||

Once the power is turned on, you will see the Debian Desktop. You now need to launch one of the programs that will talk to the Controller. | |||

*UGCS Platform (Universal G-Code Sender Platform), ( https://all3dp.com/2/universal-gcode-sender/ ) | |||

*bCNC ( https://github.com/vlachoudis/bCNC#readme ) | |||

UGCS is written in Java, and bCNC is a Python program. I refer bCNC and will document that here. | |||

'''How to Jog and position the Router:''' | |||

The LongMill does not have travel switches. ( https://resources.sienci.com/view/lm-adding-limit-switches/ ) Instead, you manually jog the router to a position that you wish to use as a starting point, and then zero the XYZ references. | |||

There is also a touch plate to assist in getting precise Z (as well as X and Y) references for you particular material. | |||

====Fusion 360 Notes and Tweaks==== | |||

The SIENCI LongMill is not currently listed in the machine library of Fusion 360. You can however import a definition using a file created by one of the members of a LongMill facebook page. | |||

Follow these instructions: | |||

*Download the file from the [https://www.facebook.com/groups/mill.one/permalink/1053271605144170/ LongMill and Mill One User Facebook Group] ( [https://drive.google.com/drive/folders/1yXLyauomSxSWQKmn3VWCcp_SljIMtC6D Longmill3030.cps] ) | |||

*Following the instructions to install this file from [https://knowledge.autodesk.com/support/fusion-360/learn-explore/caas/sfdcarticles/sfdcarticles/How-to-add-a-Post-Processor-to-your-Personal-Posts-in-Fusion-360.html AutoDesk] on how to import a CPS file | |||

* | |||

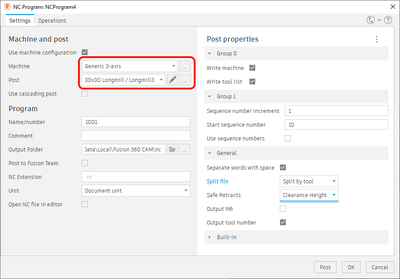

[[File:143 Add-Longmill-Postprocess.png|400px|Screen shot of Fusion 360 Post Processor defined]] | |||

Also, one note on Fusion 360 on their Resources website: | |||

<nowiki>**</nowiki>To avoid potential issues with Fusion 360, we also recommend you make the following checks to your post-processor: | |||

*'''G28 Safe Retracts''' set as “Clearance Height” | |||

*'''Output M6''' set as “No” | |||

*'''Output Tool Number''' set as “No” | |||

====Reference links==== | |||

*[https://www.youtube.com/watch?v=lQ-MYnyxh7M CNC Basics - What You Need To Get Started -> https://www.youtube.com/watch?v=lQ-MYnyxh7M] (Has a LongMill in the demo) | |||

*[https://www.youtube.com/watch?v=_Rt5sC9DrEQ&t=297s CNC Basics - Make Your First Cut -> https://www.youtube.com/watch?v=_Rt5sC9DrEQ&t=297s] | |||

*[https://iliketomakestuff.com/how-to-use-easel/ CNC Basics - How to use Easel (free CNC software) -> https://iliketomakestuff.com/how-to-use-easel/] | |||

*[https://www.youtube.com/watch?v=iqnvzxuXFTQ Fusion 360 CAM tutorial for CNC beginners - Making "Kevin" -> https://www.youtube.com/watch?v=iqnvzxuXFTQ] | |||

*[https://www.youtube.com/channel/UCQffithtlX96uayLQ4fQlFg Bucky's Customs YouTube Channel (Lots of LongMill how to video's) --> https://www.youtube.com/channel/UCQffithtlX96uayLQ4fQlFg] | |||

* | |||

<hr> | |||

===Planned Updates=== | |||

*Add Power Switch for Router Power | |||

*Add E-Stop switch | |||

*Add e-relay for Router Power (Power control in G-Code) | |||

*Add Travel Switches. | |||

<hr> | |||

===Tool history=== | |||

[[File:143_LongMill-01.gif|200px|thumb|right|Original CNC when donated]]The LongMill CNC was donated by Peter Carless. He built the stand as well as the shelf and power bars for the electronics. | |||

The first training session has yet to be held at the date of writing | The first training session has yet to be held at the date of writing | ||

<br /> | |||

Latest revision as of 04:35, 6 October 2024

| |

| Type | LongMill Wood CNC |

| Make/Model | Industrial |

| Serial number | N/A |

| Original owner | Protospace |

| Loan status | Current |

| Arrival date | Oct 28th, 2021 |

| Location | Wood Shop |

| Functional status | Waiting for training material |

| Usage permissions | Members & Friends Only |

| Certification | Must complete CNC-LongMill Certification |

| Wiki-ID | 143 |

| Label | 1.0" 1.5" 2.0" |

Update: (10/21/2022)

The LongMill has been installed on the shelf in the "Large Projects" area, along side of the MiniCNC.

Machine Overview

This is a SIENCI (pronounced "CNC") Labs LongMill ( See https://sienci.com/product/longmill/ ) with the short rails. The web page says it is 12"x12" but in fact it is more like 10"x13".

The controller is an Arduino running GRBL.

There is a ton of valuable reference material on their "Resources" website. See -> https://resources.sienci.com/view/lm-welcome/

For technical Details see https://resources.sienci.com/view/lm-longboard-documentation/

Bed size: 250mm x 340mm (10"x 13"). The Z travel is 105mm. The clearance below the gantry is also about 105mm so this is the thickest material that could be mounted, although the router can be adjusted higher if the material has the right shape to clear the gantry. There is about a 60mm offset from the gantry to the router bit (in the Y axis) that could be used for taller pieces.

Spindle: Makita Trim Router Model RT0701C ( https://www.makitatools.com/products/details/RT0701C). The Makita Router has a 1/4" collet, and a also a 1/8" collet insert. Manually controlled, this router has variable speed spindle from 10,000 to 30,000 RPM. It is manually controlled (Not controlled in software). There is a collection of bits in the red toolbox under the CNC.

Currently, the Spindle power is not controlled by the CNC Controller and must be turned On/Off manually. This is on the list of improvements.

Machine Control: GRBL on a SIENCI Milling Labs LONGBOARD Controller.

User Interface: The Raspberry PI that was originally installed has been replaced with a faster and more robust "nanoPC" (model nT-A3800) connected to the Controller via USB. It has GSender, Universal G-Code Sender (UGCS)as well as bCNC installed.

PC Login: The Debian logon on is automatic on startup, so you do not need to log on. But if you need it for any reason, it is protospace/protospace.

Hold down method: Screws, nails, clamps(must make these).

Note that the base plate mounting board is MDF but IS NOT A SACRIFICIAL BOARD. The mounting board has threaded inserts on a 10cm x 10cm grid. You can supply your own hold down board with whatever system you wish. Simply drill holes in your board so that you can mount it to these threaded inserts. The threaded inserts are 10x24. There are a sample supply of different length screws for you to use.

Dust collection?: Yes, requires a ShopVac.

Probing: plate style. Plate is 15mm thick as well as X and Y 10mm offset.

Suitable stock materials: Wood, plastics, foams, other.

Unsuitable stock materials: Zero metal, metal alloy, or metal composites are to be cut on this. If the CNC machine was on the rolling cart, it possibly could be moved outside to do some aluminum milling, but for now don't do it.

Instructions and Training

How to turn on the machine

The main power is turned on by turning on the common power bar for the shelf. This also turns on the lights as well as power for the MiniCNC

There are 2 power switches to be turned on (not counting the monitor).

- The nanoPC has it's own power supply plugged into the power bar. There is a power switch on the front of the PC.

- The SCENCI Longboard has a power switch.

- And finally, when you want to start the Router, you also need to turn on the switch on the router. (Note: that this may be put on a more convenient switch and even maybe software control in the future. )

Once the power is turned on, you will see the Debian Desktop. You now need to launch one of the programs that will talk to the Controller.

- UGCS Platform (Universal G-Code Sender Platform), ( https://all3dp.com/2/universal-gcode-sender/ )

- bCNC ( https://github.com/vlachoudis/bCNC#readme )

UGCS is written in Java, and bCNC is a Python program. I refer bCNC and will document that here.

How to Jog and position the Router:

The LongMill does not have travel switches. ( https://resources.sienci.com/view/lm-adding-limit-switches/ ) Instead, you manually jog the router to a position that you wish to use as a starting point, and then zero the XYZ references.

There is also a touch plate to assist in getting precise Z (as well as X and Y) references for you particular material.

Fusion 360 Notes and Tweaks

The SIENCI LongMill is not currently listed in the machine library of Fusion 360. You can however import a definition using a file created by one of the members of a LongMill facebook page.

Follow these instructions:

- Download the file from the LongMill and Mill One User Facebook Group ( Longmill3030.cps )

- Following the instructions to install this file from AutoDesk on how to import a CPS file

Also, one note on Fusion 360 on their Resources website:

**To avoid potential issues with Fusion 360, we also recommend you make the following checks to your post-processor:

- G28 Safe Retracts set as “Clearance Height”

- Output M6 set as “No”

- Output Tool Number set as “No”

Reference links

- CNC Basics - What You Need To Get Started -> https://www.youtube.com/watch?v=lQ-MYnyxh7M (Has a LongMill in the demo)

- CNC Basics - Make Your First Cut -> https://www.youtube.com/watch?v=_Rt5sC9DrEQ&t=297s

- CNC Basics - How to use Easel (free CNC software) -> https://iliketomakestuff.com/how-to-use-easel/

- Fusion 360 CAM tutorial for CNC beginners - Making "Kevin" -> https://www.youtube.com/watch?v=iqnvzxuXFTQ

- Bucky's Customs YouTube Channel (Lots of LongMill how to video's) --> https://www.youtube.com/channel/UCQffithtlX96uayLQ4fQlFg

Planned Updates

- Add Power Switch for Router Power

- Add E-Stop switch

- Add e-relay for Router Power (Power control in G-Code)

- Add Travel Switches.

Tool history

The LongMill CNC was donated by Peter Carless. He built the stand as well as the shelf and power bars for the electronics.

The first training session has yet to be held at the date of writing